Recently, some customers and friends will ask why the heat transfer printing has warping after pressing. If warping occurs, how should we correct or remedy it?

Warping of heat transfer printing is caused by the following reasons: material problems, improper hot pressing temperature, insufficient hot pressing time and equipment problems.

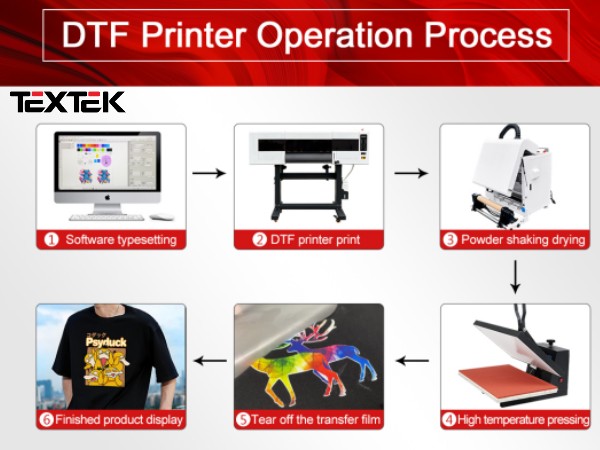

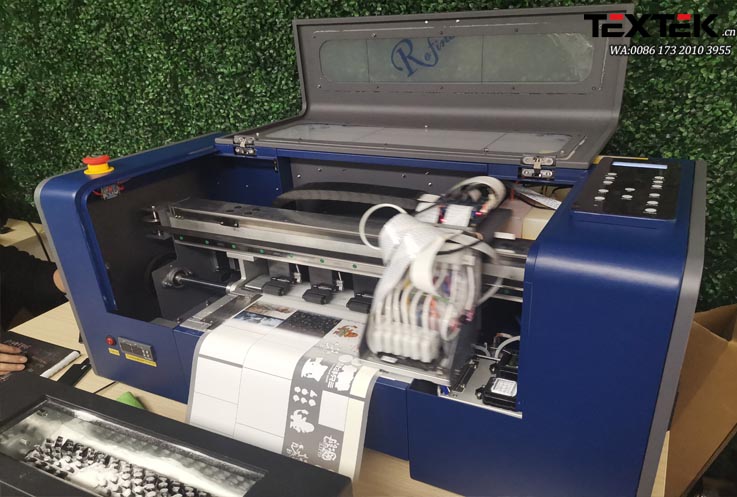

1. Material problem: DTF printing is performed on the surface of the fabric. The material of the fabric is not suitable for heat transfer. The hot pressing process will cause the fabric to deform or shrink, which will lead to edge warping.

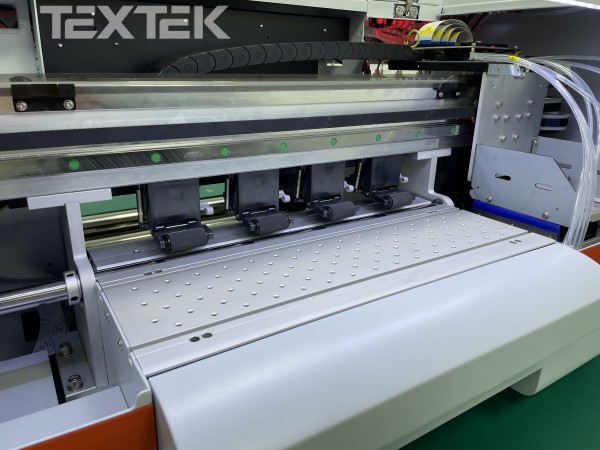

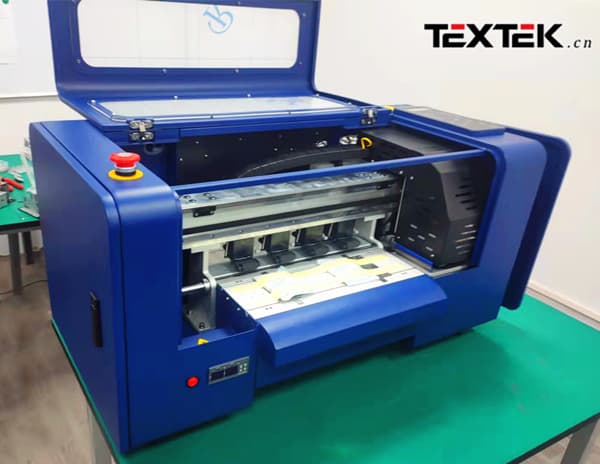

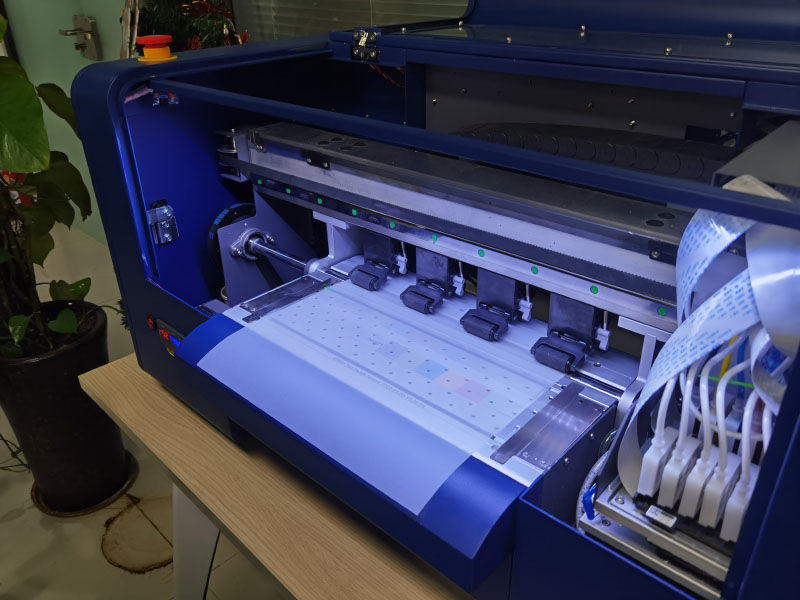

2. Improper hot-pressing temperature: When dtf printing, hot-pressing temperature that is too high or too low will cause edge warping problems. If the temperature is too high, the fabric will be excessively deformed; if the temperature is too low, the heat transfer adhesive will be insufficient and cannot be firmly bonded.

3. Insufficient hot pressing time: When DTF printing is pressed, insufficient hot pressing time will cause the heat transfer glue to not completely melt and penetrate into the fabric fibers, and the heat transfer cannot be firmly fixed, causing warping.

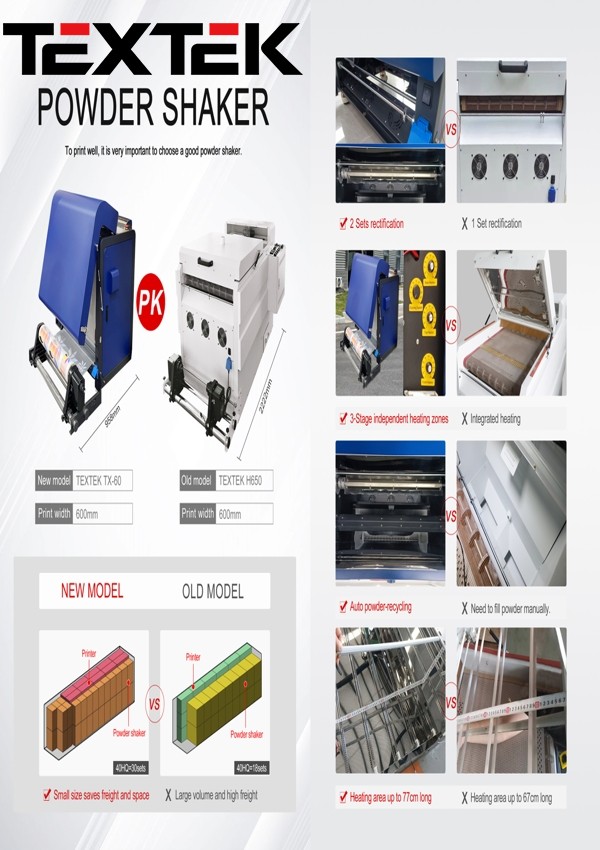

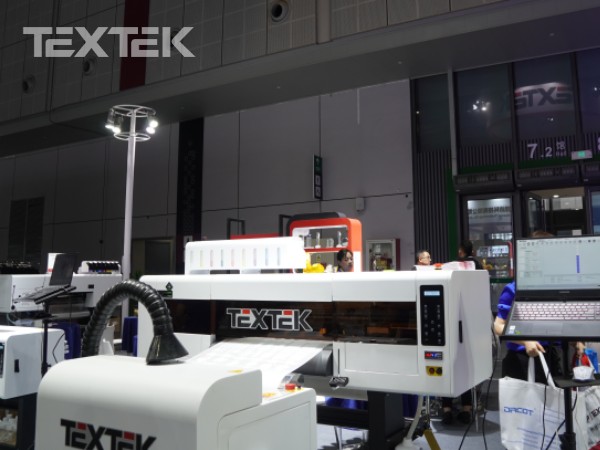

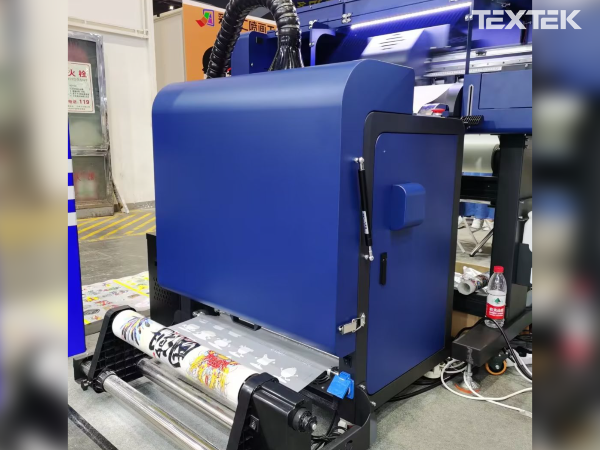

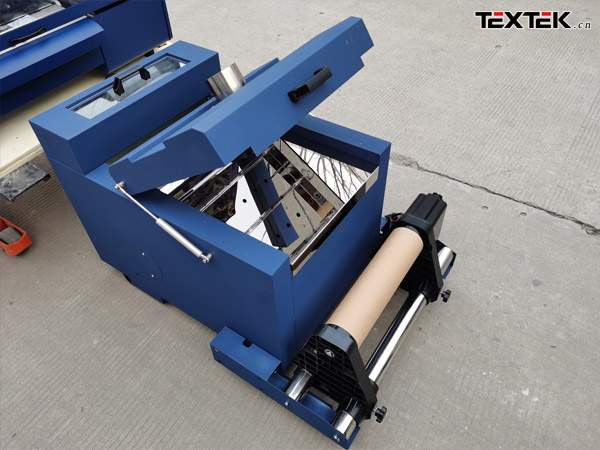

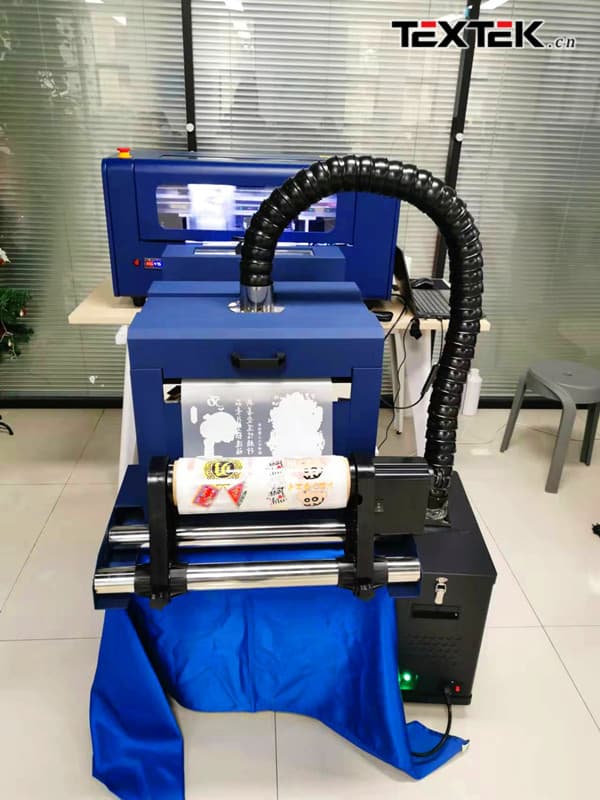

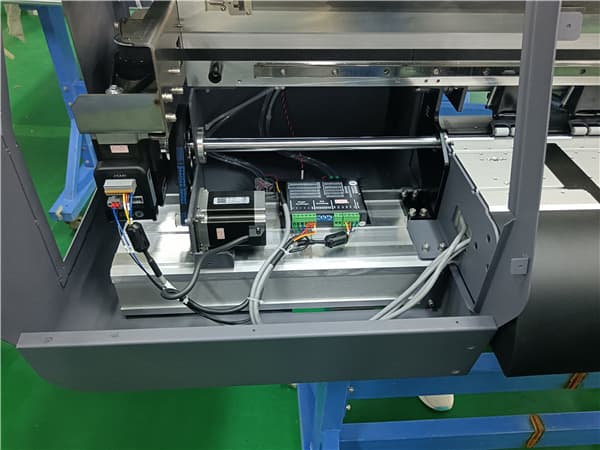

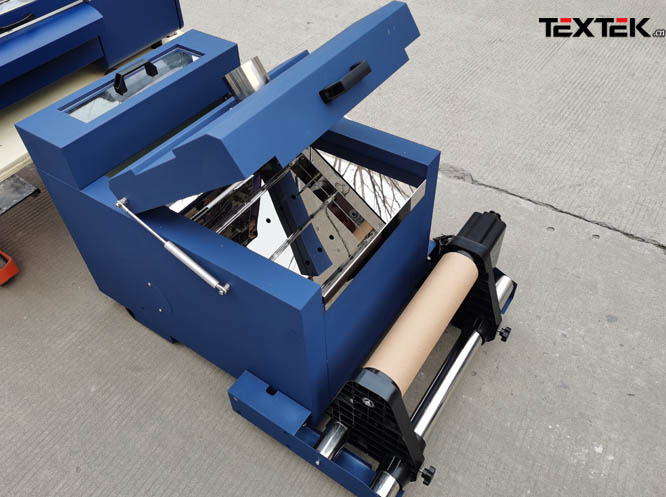

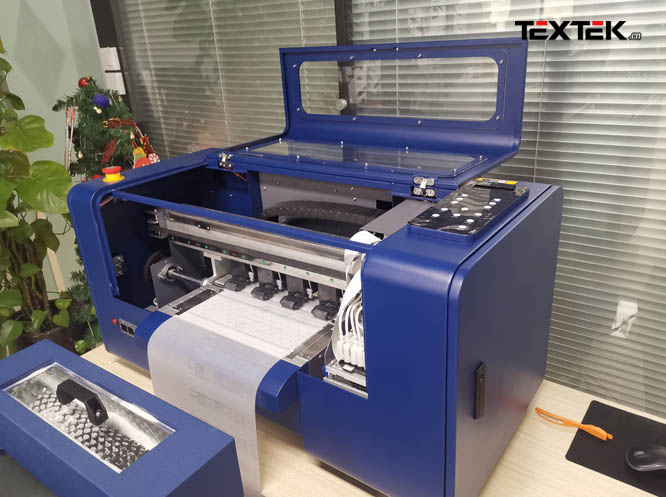

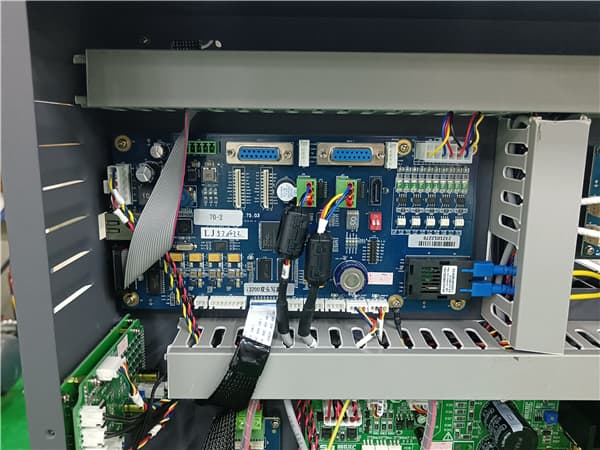

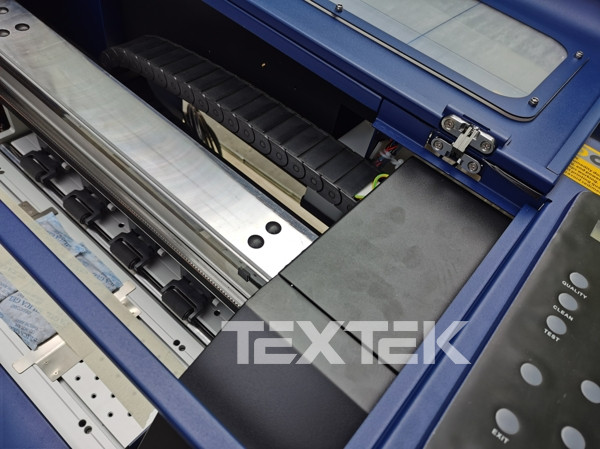

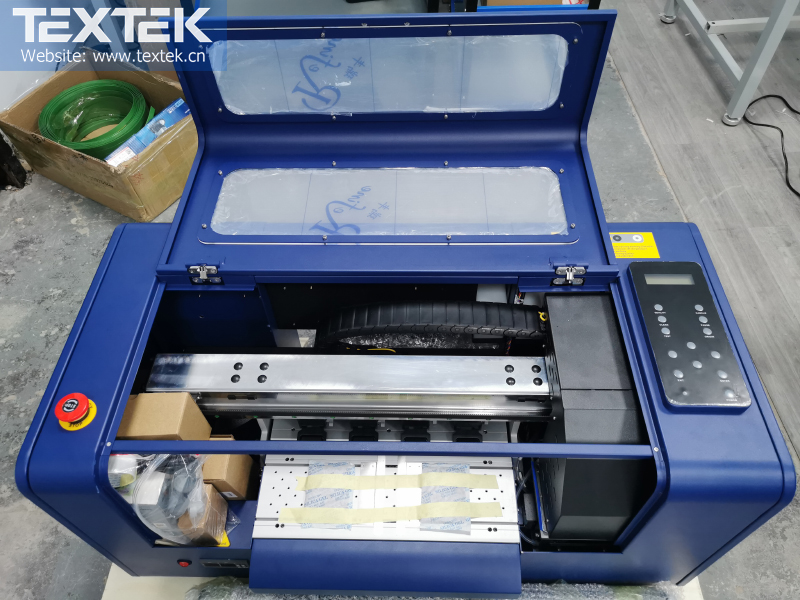

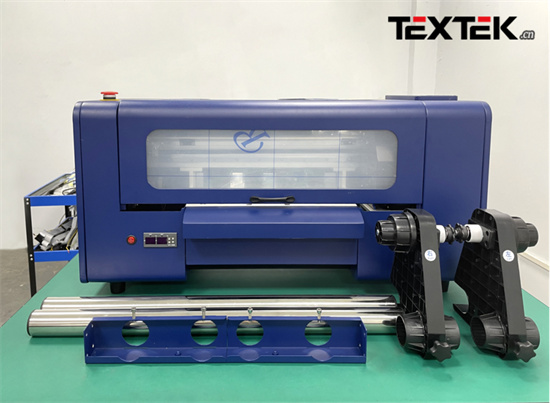

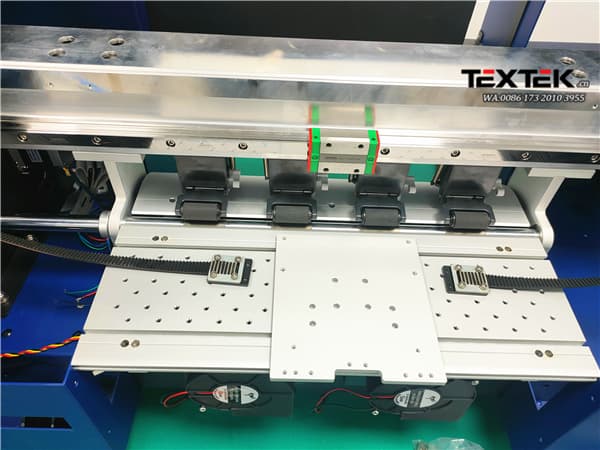

4. Equipment problems: Equipment problems such as inaccurate temperature control of the Dtf printer, uneven pressure or uneven ironing head lead to uneven heat transfer, resulting in edge warping. In order to avoid the problem of edge warping in dtf printing, you can consider the suitability of the material when selecting fabrics and heat transfer designs, and ensure that the appropriate heat transfer temperature and time are used.

In addition, using reliable quality DTF printing equipment and correct operation methods can also help reduce the occurrence of edge warping problems. In actual operation, it is best to test a small piece of fabric first to determine the best heat transfer parameters. If you find edge warping problems after pressing, you can press again to achieve the desired effect.