Creating custom team tees has never been easier, thanks to the advanced capabilities of the 60cm DTF (Direct-to-Film) printer. This versatile printing technology allows you to produce high-quality, vibrant designs that capture your team’s spirit. Here’s a step-by-step guide to help you get started.

Step 1: Design Your Artwork

Begin by designing your artwork using graphic design software. Make sure to include your team’s logo, colors, and any custom text, such as player names or slogans. Ensure the design is scaled appropriately for the shirt size and type you plan to print. Using vector files can help maintain quality.

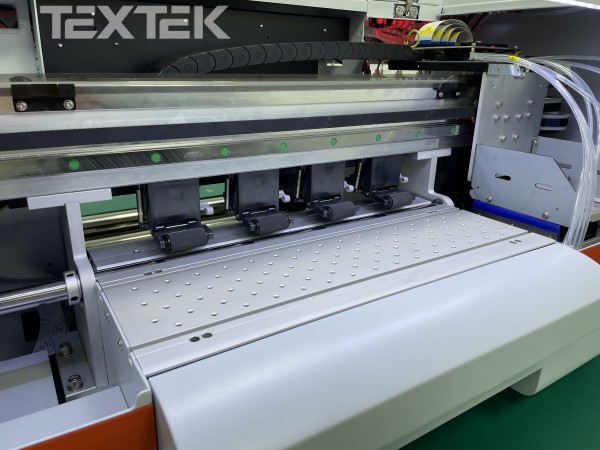

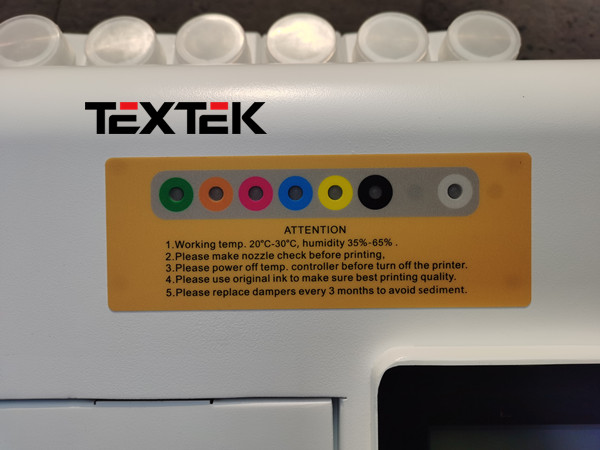

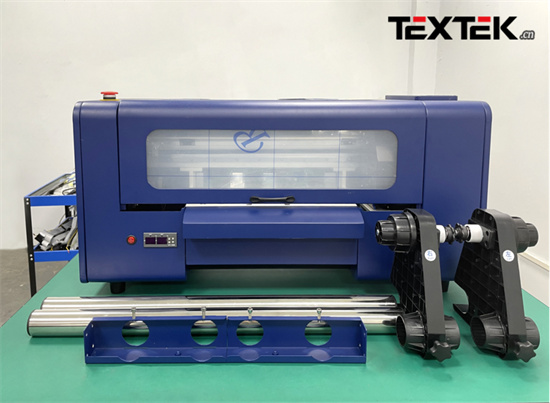

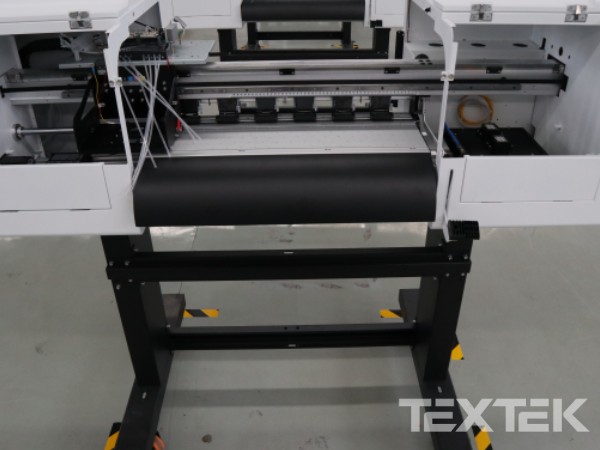

Step 2: Prepare the Film

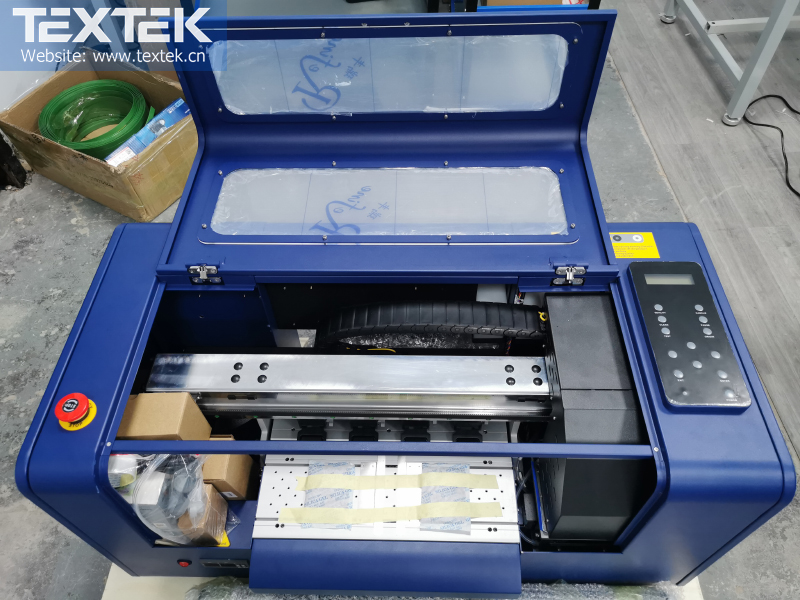

Once the design is finalized, print it onto the special DTF film using the 60cm DTF printer. This printer ensures that the colors are vibrant and the details are sharp. Remember to use the correct printing settings for optimal results, taking into account the fabric type and ink requirements.

Step 3: Apply the Adhesive Powder

After printing, immediately sprinkle adhesive powder over the wet ink on the film. This step is crucial as it helps the design adhere to the fabric during the heat transfer process. Ensure even coverage for the best results.

Step 4: Cure the Ink

Next, cure the printed film with the adhesive powder using a heat source, typically a powder shaker or oven. This process solidifies the adhesive and prepares the design for the transfer.

Step 5: Heat Press Your Tees

Once the film is ready, position it on the t-shirt where you want the design to appear. Use a heat press machine set to the recommended temperature and pressure settings. Press the design onto the fabric for the specified time to ensure it adheres properly.

Step 6: Peel and Reveal

After pressing, let the transfer cool slightly, then carefully peel away the film. Your custom design should now be firmly bonded to the t-shirt, ready to show off your team spirit!

Step 7: Quality Check

Inspect the finished product for any imperfections. Ensure the design is well-adhered and that colors appear vibrant. This step is essential for maintaining quality, especially if producing multiple tees.