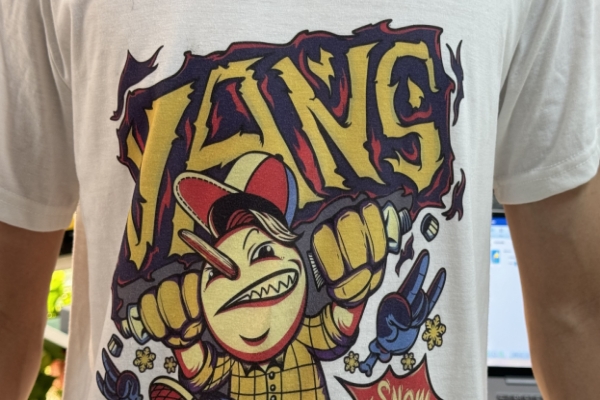

If your washing or drying is done with high-temperature water, then this could be the problem. However, print breakage can also be caused by other reasons as follows:

a. Wrong washing method – Garments with DTF prints are recommended to be washed on the reverse side and washed/dried at a low temperature. High water temperatures or high speed rubbing against the surface may break the bond between the fabric and the ink, resulting in print breakage.

b. Poor white ink base – Usually white ink is used as the base color for printing and its quality significantly affects the overall printing performance. Check that the white layer prints well before transferring the print to the fabric.

c. Poor powder curing or pressing – If the adhesive powder is not cured thoroughly, the residual moisture will create air pockets and greatly affect the pressing effect.

Warm tip – If you want to double-ensure the result, you can do a second pressing after the first one (hot pressing at 145°C and a pressing time of 20 seconds).

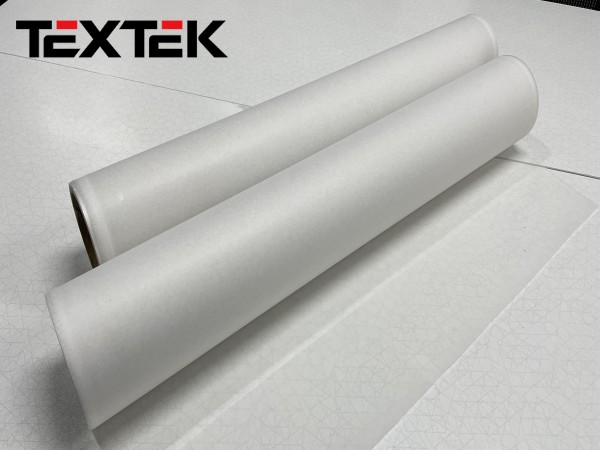

Unsuitable hot melt powder – Some specific fabric substrates require specific hot melt powders. For example, rougher fabrics require a coarser binder powder (200 mesh, particle size below 250 microns) for better curing and pressing results.