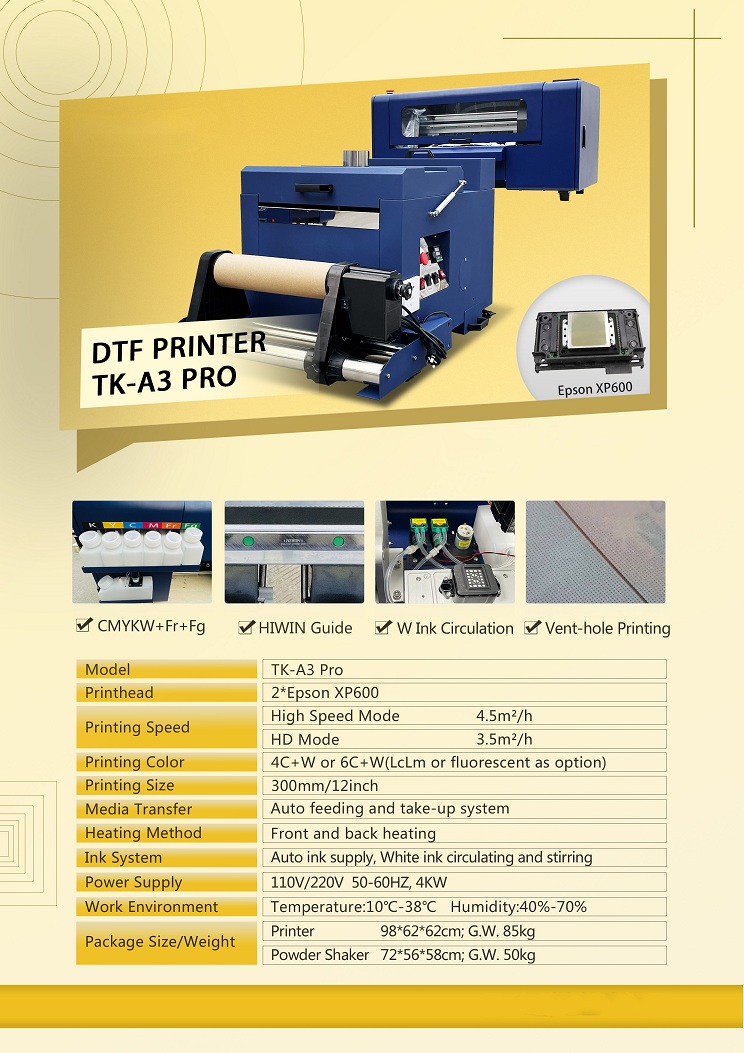

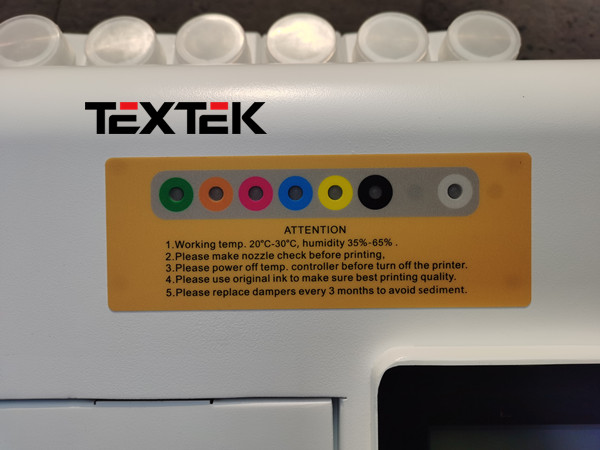

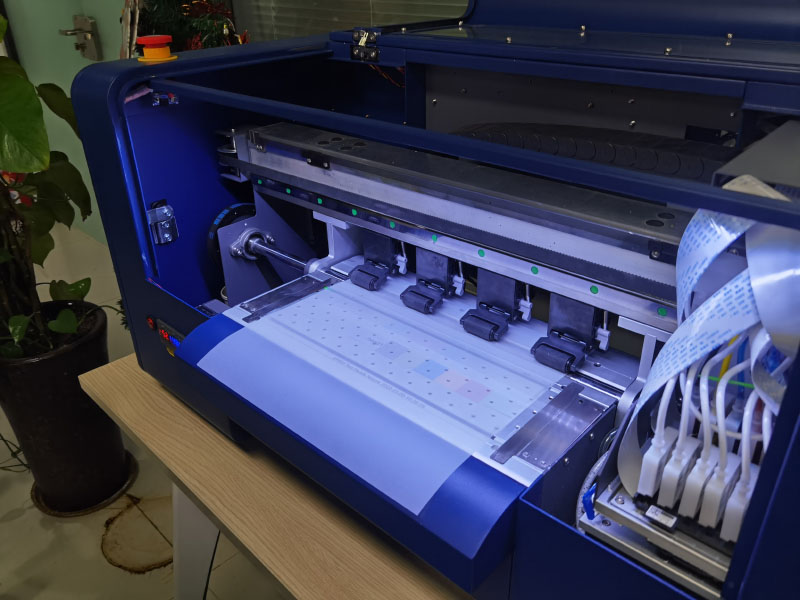

In a humid environment, the operation of a DTF printer is still prone to many problems, such as condensation of water droplets on the mainboard, nozzle, etc., causing short circuits or even burning. In addition, in such an environment, the ink on the screen printed by the white ink heat press machine is difficult to dry, which greatly reduces the work efficiency. This has to be said to be a very troublesome problem.

If the production workshop of the DTF printer is too humid, there may be a series of problems such as fading and water melting of the picture. In most cases, we mistakenly think that this phenomenon occurs because of the ink problem, which brings great obstacles to solving the problem and finding the specific cause. Therefore, the white ink heat press machine manufacturer believes that we should try to keep the room dry in the studio where the printing machine is stored, close the doors and windows, prevent the spread of outdoor moisture, and maintain a relatively high indoor temperature, and then use a large fan to air dry the printed image.

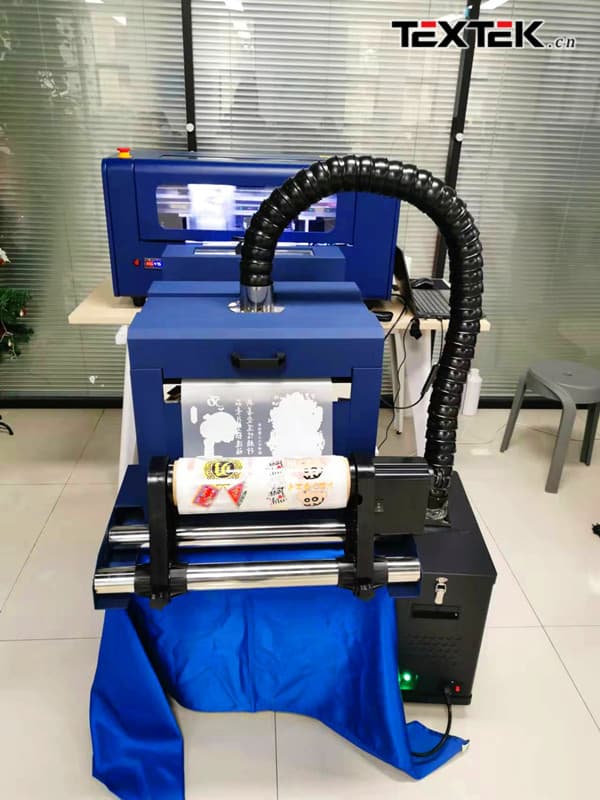

The printing film of the DTF printer is mainly composed of the printing film and the coating on the film. It is easier to absorb moisture and get damp. When the printing film is damp, the ink will spread when printing. Once the printing film is damp, it can no longer be used. All consumables of DTF printers need to be well protected and stored in a fixed location. Remember not to have direct contact with the ground or walls to avoid damage to the consumables and thus losses due to moisture and other reasons.