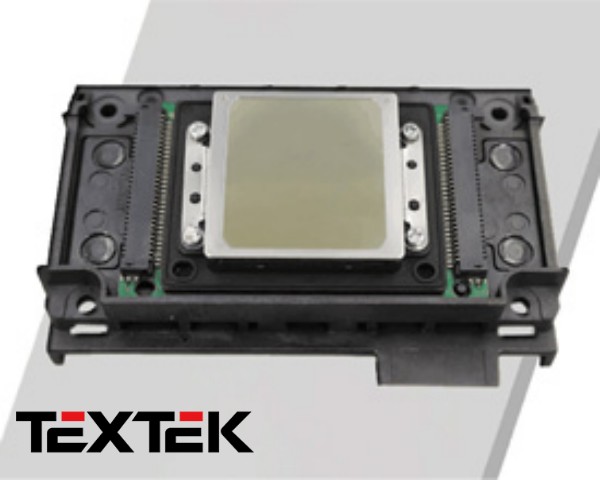

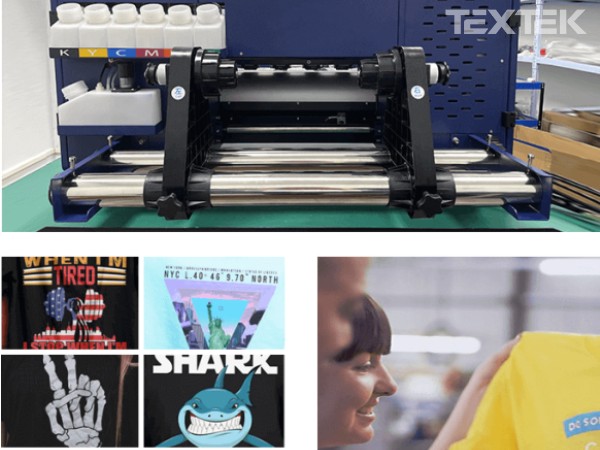

The temperature and humidity of the working environment have a great impact on the operation of the printer. The most obvious impact of the temperature drop on the DTF heat transfer printer is that the nozzle is prone to clogging, which leads to ink breakage, needle skipping, slanted spraying, ink flying, etc. This is because the viscosity of the ink increases with the decrease in temperature, and the ink droplets condense on the nozzle hole. If it is a slight blockage, you only need to clean the nozzle to solve the problem. If it is a severe blockage, then you have to replace the nozzle with a new one.

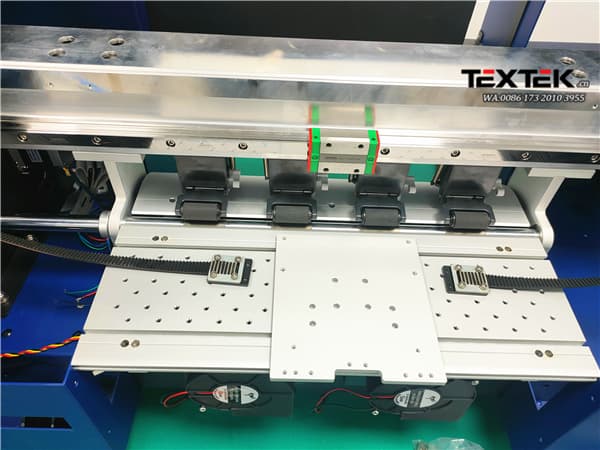

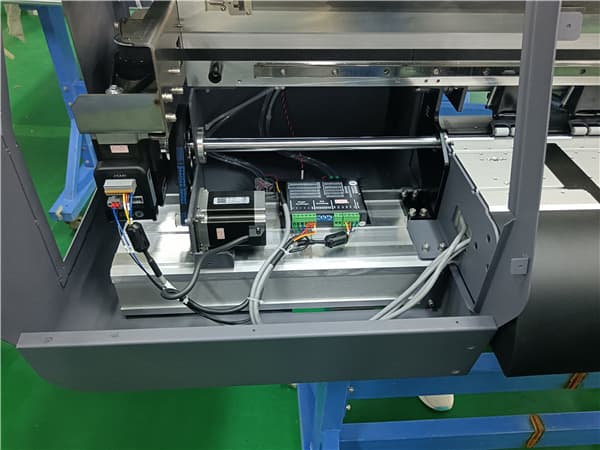

In winter, the temperature is low and the humidity is relatively low. Dry air can easily cause the edge of the DTF heat transfer printer to warp when printing, and in severe cases, it may cause damage to the nozzle and motor.

Therefore, you must pay special attention to the temperature and humidity of the working environment of the white ink heat transfer printer. The temperature range suitable for DTF heat transfer printer is 18℃-30℃, and the humidity range is between 35%-65%. In a dry-weather environment, do not place the DTF heat transfer printer in an outdoor environment. If the temperature in the DTF heat transfer printer operating room is low, you can use air conditioning to increase the temperature and humidify.

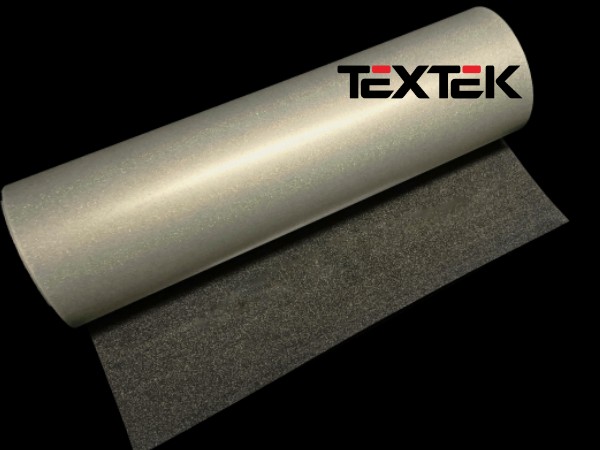

Maintaining the DTF heat transfer printer well can effectively reduce printer failures. You also need to pay attention to the daily maintenance of the equipment to avoid dust accumulation. After the equipment finishes printing every day, you can cover the printer with a dust-free cloth to reduce the intrusion of dust. Finally, pay attention to the cleaning of accessories. You need to clean the nozzle before and after printing to ensure that the nozzle is in good condition before printing or turning off the printer.