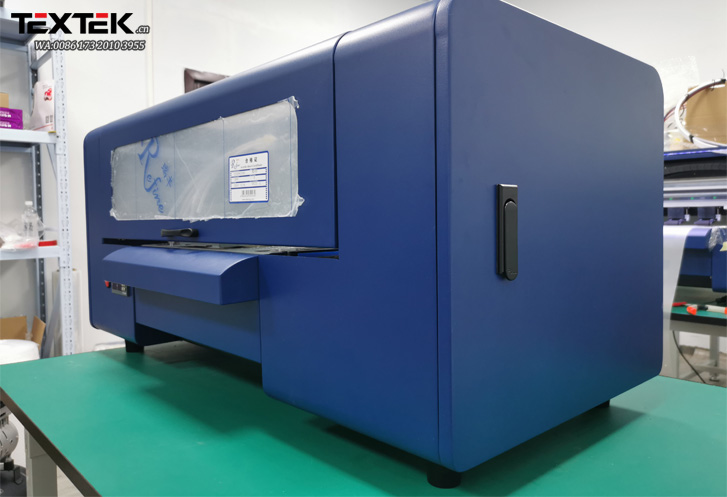

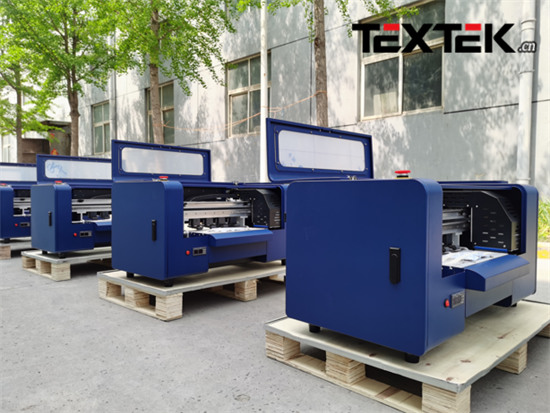

Direct to Film (DTF) Printing Solutions

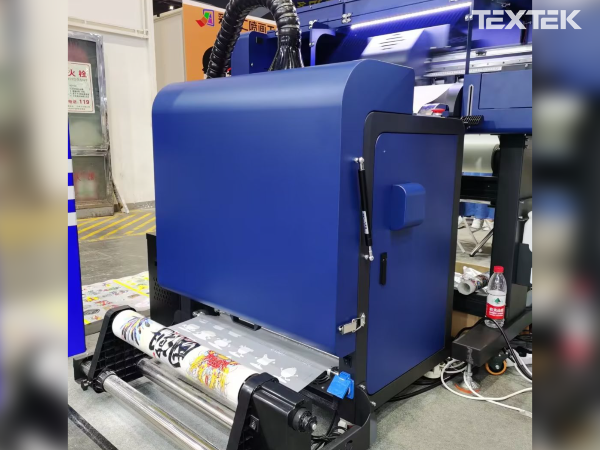

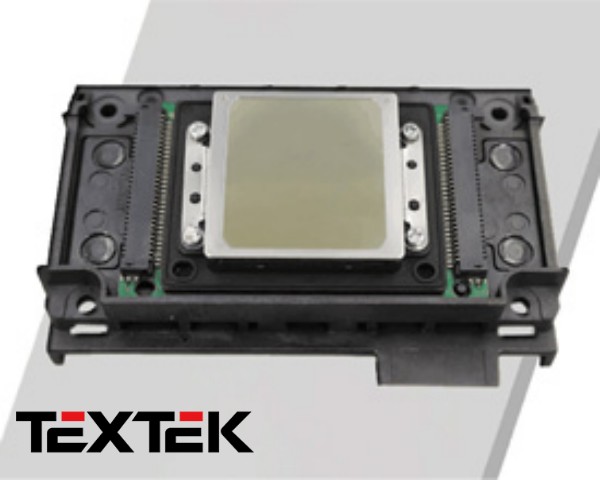

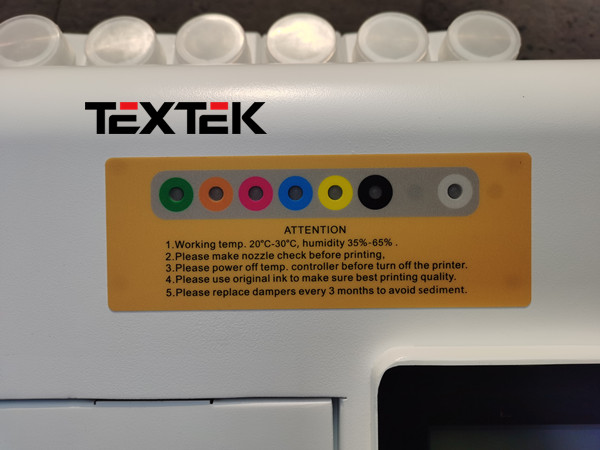

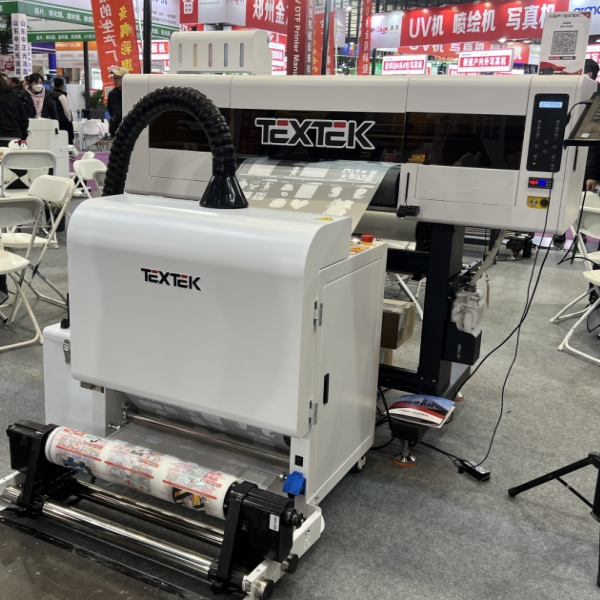

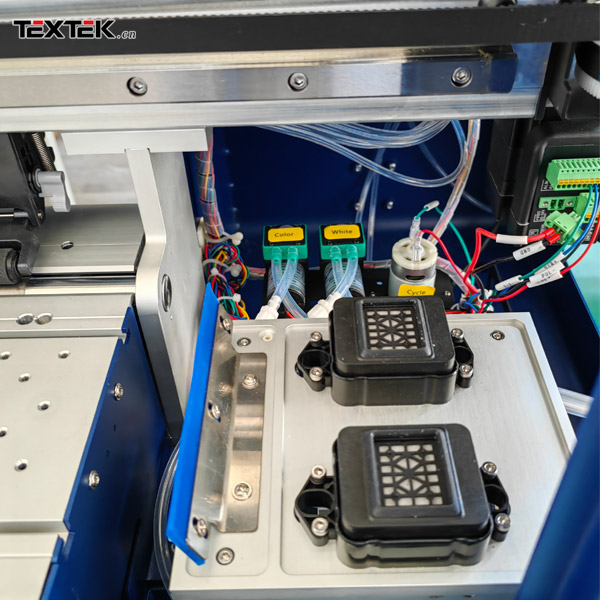

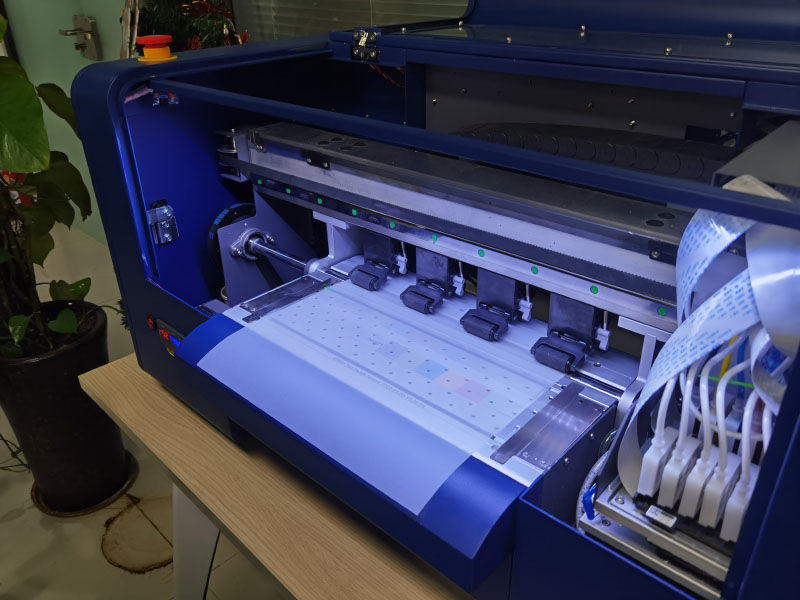

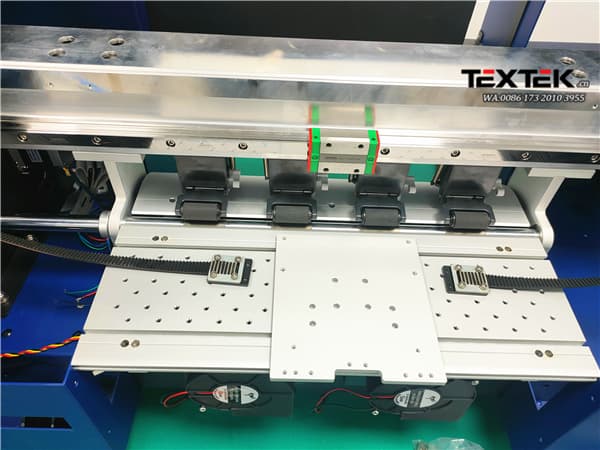

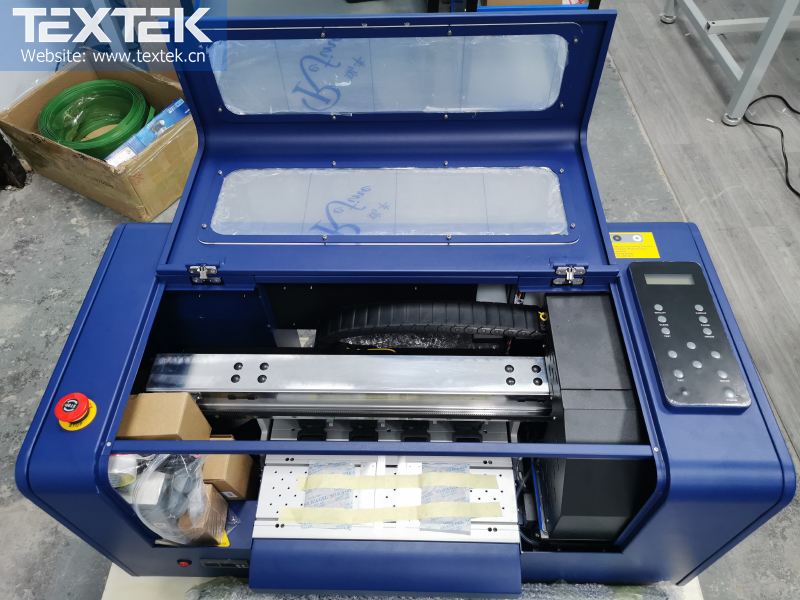

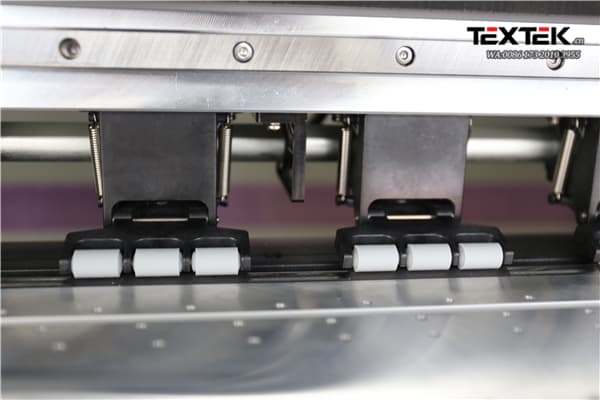

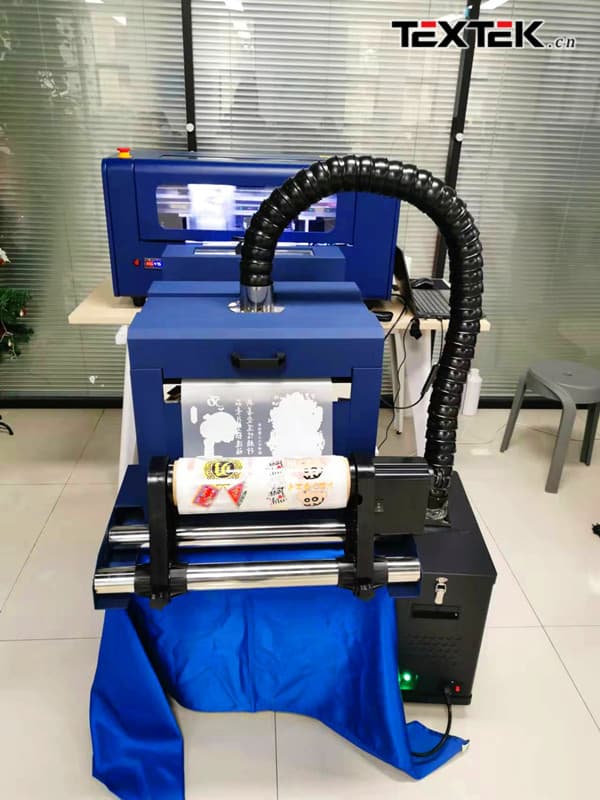

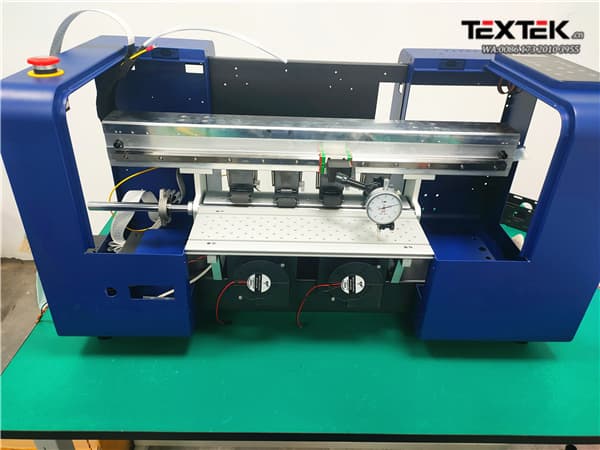

Direct to film (DTF) printing solution do you want to have your own direct to garment printer? The cost of owning and maintaining one is too high for you now? Well, due to the progress of technology, a new breakthrough process has emerged, which can be comparable to DTG printing. This may be the perfect upgrade of your clothing customization business. Printing technology directly to film is here, and it will continue to exist. There are also good reasons. But what is the direct cause of film printing? Direct to film printing (DTF) is a new technology that allows users to print designs on special films. These films are then transferred to the selected clothes using an adhesive, which can be used as long as screen printing. Like most heat transfer processes, high-quality printers and hot presses are necessary to maximize the use of this process. What do I need? In DTF printing, it is important to have high-quality ink to avoid print head blockage.

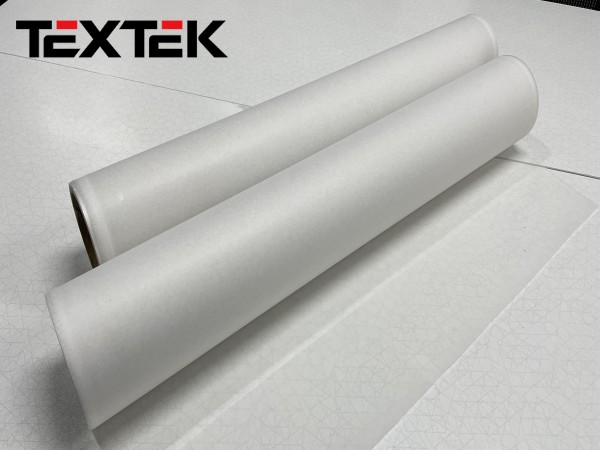

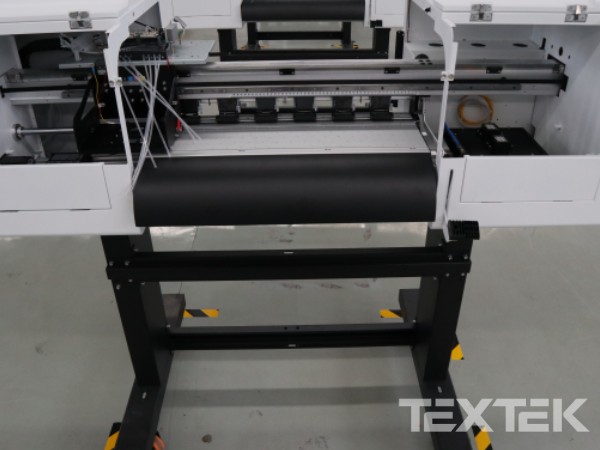

Another important material in this process is printable film. Ordinary PET film is not suitable for DTF printing. Unprocessed low-quality film may stain the print, unacceptable adhesives, or completely damage the garment. This specially treated film can withstand high temperatures of up to 210 degrees Celsius and hot pressing for up to 40 seconds. This high-quality printable film is compatible with any desktop or large format DTF printer. Finally, you need a high-quality adhesive to hold them together. What is the process like? Design – use your favorite graphic design software (such as Photoshop, illustrator, Corel Draw, etc.) to make your own design. Print – print your design on our professional film. Depending on the printer used, it will print the color first, and then print a white top layer as the bottom layer of the shirt. Application – apply the powder adhesive evenly to the printed film. If there is excess, shake it off. Baking – use a hot press or oven to melt the adhesive onto the film. Hover the hot pressing plate over the top of the adhesive to ensure uniform heat throughout the process. Press – press your design onto a base like a T-shirt. Suitable for cotton, polyester, leather, cardboard, aluminum and other flat, rough and hard materials.