What is the difference between white ink direct injection and white ink heat transfer? Which process is better?

In the field of textile printing, white ink heat transfer and white ink direct injection are two common processes. Although they both use white ink as the main printing material, there are significant differences in practical application and operation. This time TEXTEK will compare these two processes in detail so that everyone can understand their respective characteristics and applicable scenarios.

White ink direct injection process

First, let me introduce to you the white ink direct injection process.

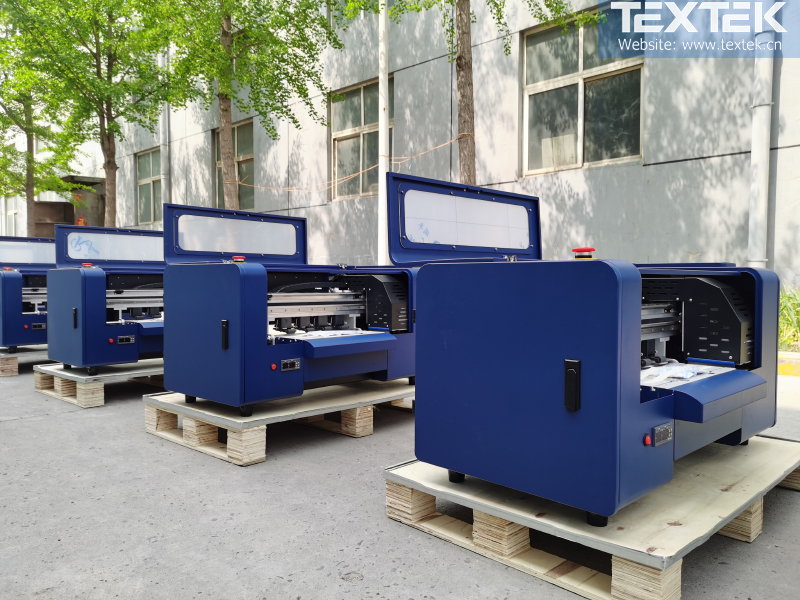

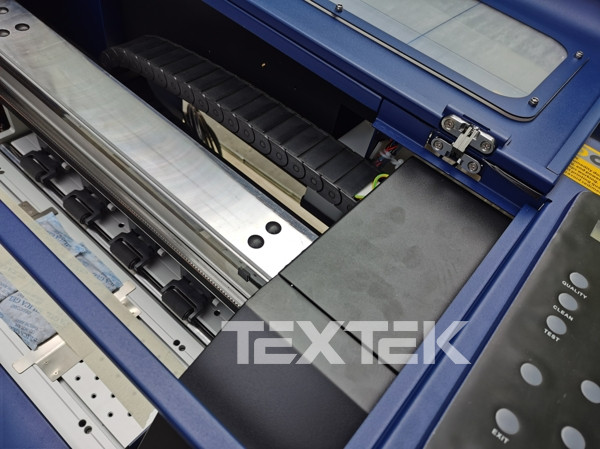

The white ink direct-injection process is easy to understand. It means that special ink is directly printed on the fabric through a white ink direct-injection printing machine, which can present delicate color transitions and achieve beautifying and decorative effects.

In terms of operation, the white ink direct printing process is relatively complex and requires fabric sizing, steaming, washing and other steps. Prior to printing, a treatment liquid must be sprayed onto the fabric (PS: different treatment liquids must be used depending on the type of fabric). Next, the fabric is placed on a direct-injection printer for printing. After printing, post-fixation processing is required to complete the printing process.

In terms of the fabrics that can be used, the direct-injection white ink process has greater fabric limitations. Generally, it can only be used on pure cotton fabrics or fabrics with higher cotton content (generally, the cotton content is not less than 75% and the effect is better. It can be used on other fabrics. The effect is not good), and the scope of application is relatively limited.

White ink heat transfer process

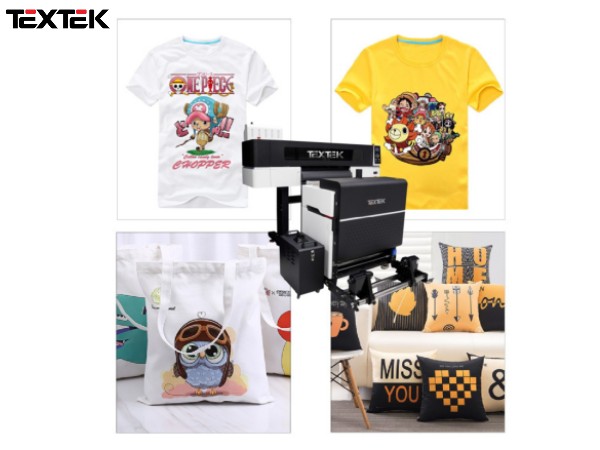

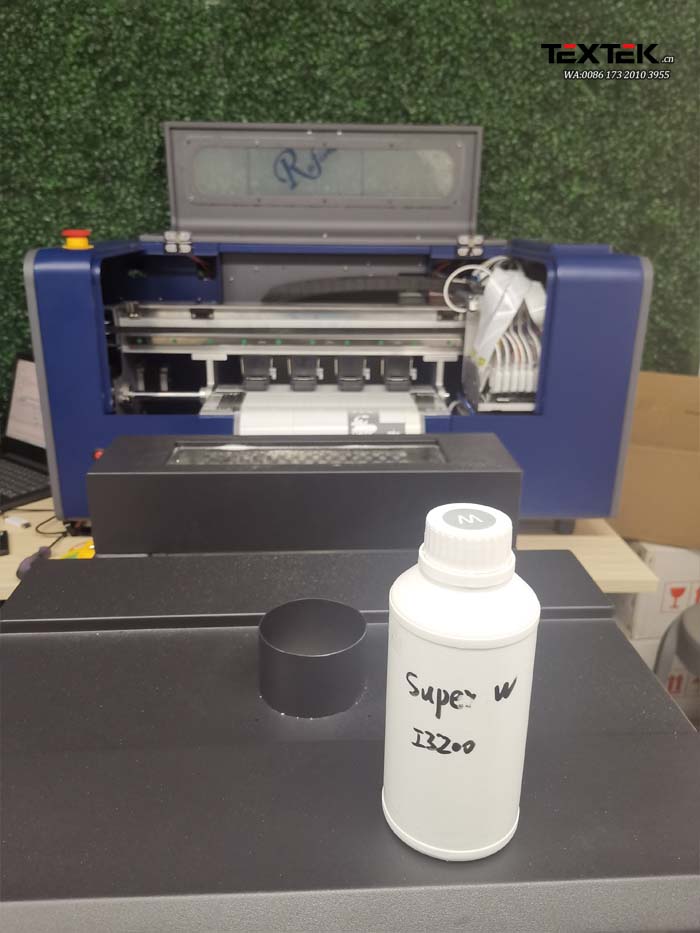

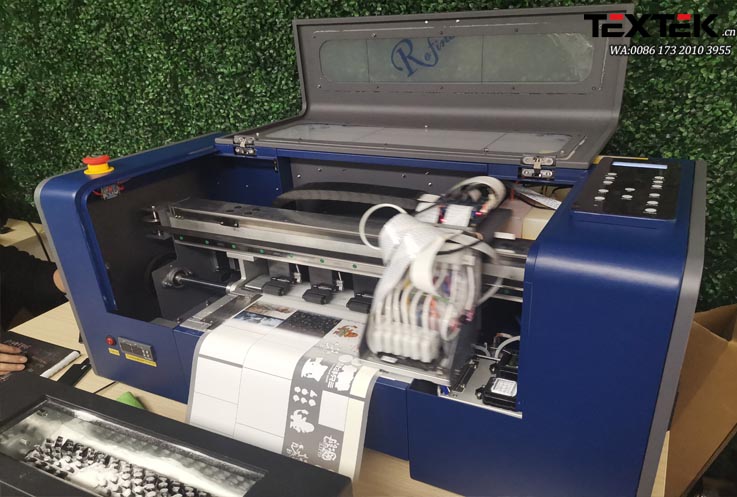

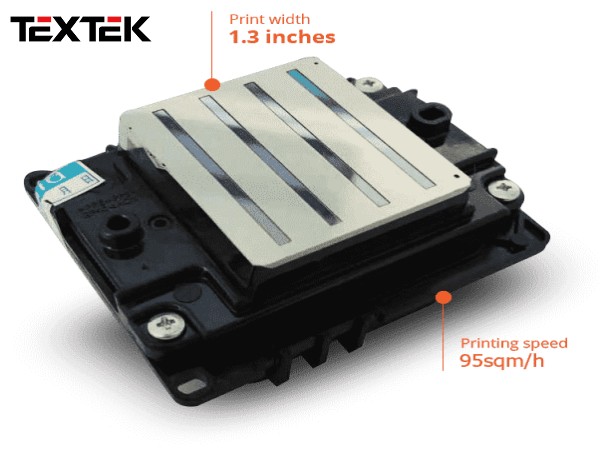

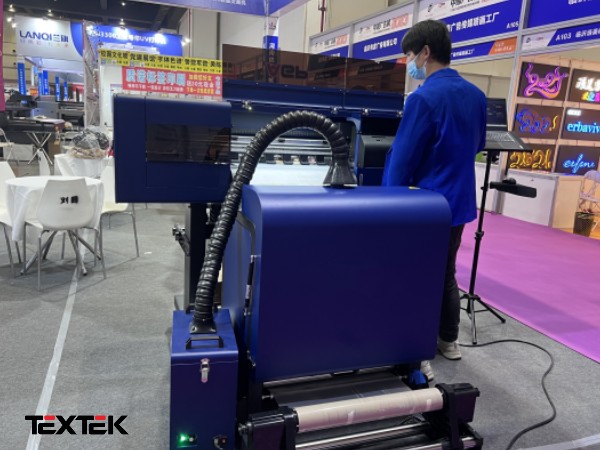

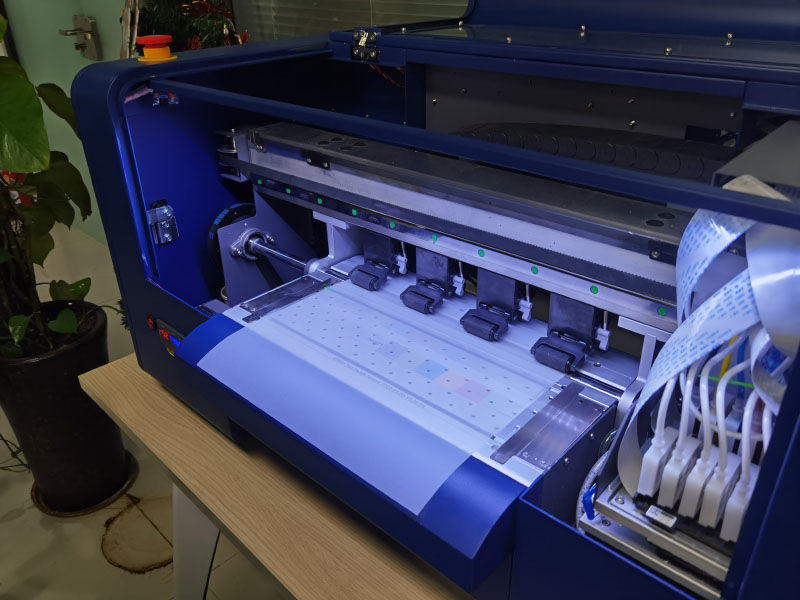

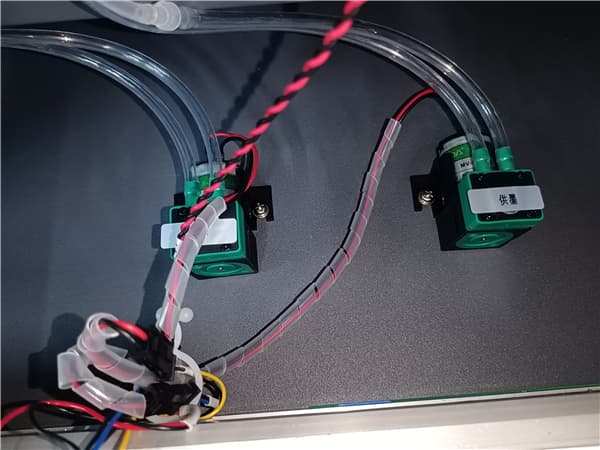

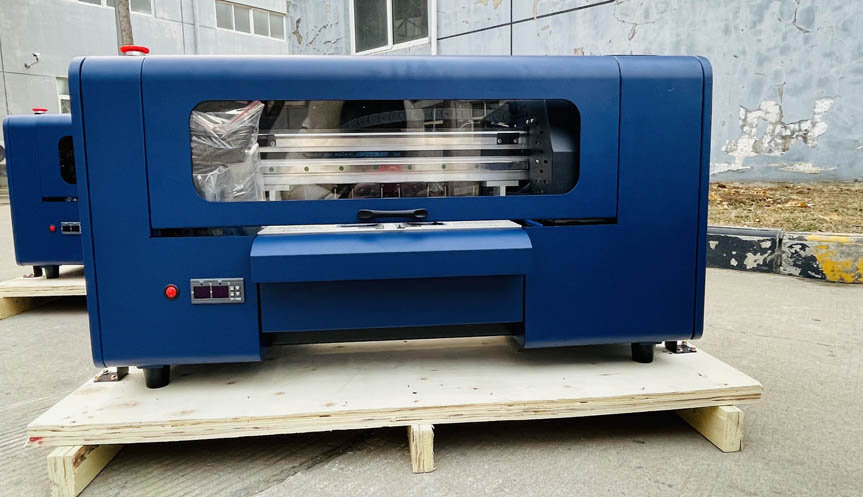

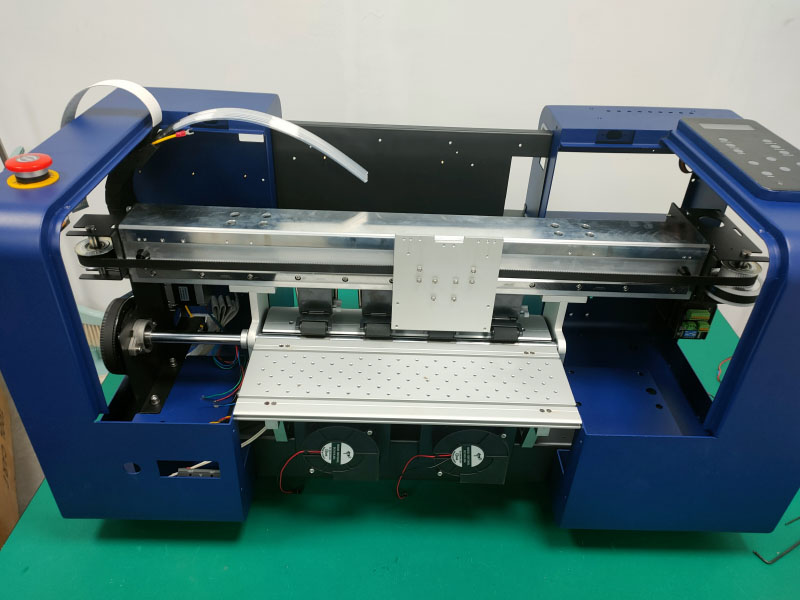

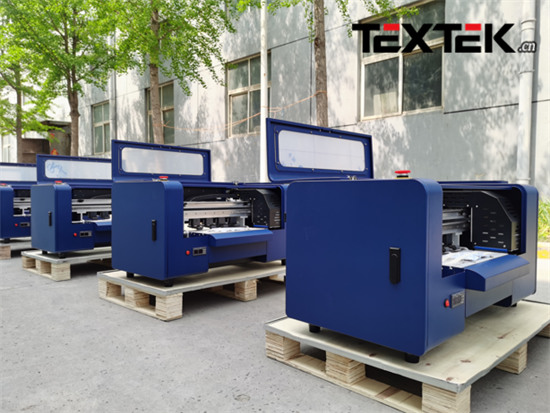

White ink heat transfer process is to use the dtf printer to print the pattern directly onto the PET printing film, and then use the pressing machine to transfer the white ink heat transfer onto the fabric after powdering, shaking, and drying by the shaking machine. The whole process is relatively simple, one person can complete the operation, minimizing labor costs.

The process is not picky about the color, fabric and pattern, whether in clothing, shoes, pillows, school bags or canvas bags and other products, including cotton, polyester, non-woven fabrics, and even in the processed leather to achieve high-quality printing, in the majority of fabrics on the market can have a good color display effect. But white ink heat transfer is not all disadvantage, its breathable feeling is poor.