03

Nov

Jumping into DTF printing is exciting. You've probably spent a lot of time picking out the right printer and inks to make those killer designs. But here’s a piece of advice from those of us who've learned the hard way: if you want your prints to actually last on a shirt, you need to talk about the DTF oven.

This isn't just a "nice-to-have" gadget. It's the piece of the puzzle that takes your design from looking good on film to being permanently fused onto fabric. Skipping it is like baking a cake and taking it out of the oven after five minutes—it might look done, but it's going to fall apart.

Let's break it down. After you print your design onto the special PET film, you sprinkle that magical adhesive powder all over it.That powder is what makes the design stick to the t-shirt later.

But in its powdery form, it's useless. It's like glitter; it gets everywhere and doesn't stick to anything properly.

The DTF oven's one job is to melt that powder perfectly. It heats the film evenly, turning that loose powder into a smooth, solid, tacky layer of glue that's bonded right into the ink. This process is called "curing." Without it, your design will feel gritty, won't stick well to the fabric, and will probably crack and fade after its first trip through the washing machine.

When you're starting, you look for ways to save money. You might think, "Can't I just use a heat press for this?"

Well, you can try. But you'll quickly see the problems. A heat press squishes the film with a hot platen, which can smear the wet ink and melt the powder unevenly. You'll get spots that are too hot and others not hot enough. The result? A transfer that's flawed before you even press it to a shirt.

A dedicated DTF oven is different. It works like a professional pizza oven, using circulating hot air to cook everything evenly from all sides. No hot spots. No smushing. Just a perfectly melted, consistent glue layer every single time. For anyone planning to do more than a couple of test prints, the oven isn't a luxury—it's a necessity for professional results.

.jpg)

Using the oven is pretty straightforward, which is a relief for busy shop owners.

Load It Up: After you've printed and powdered your film (shaken off the excess), you just lay it flat on the oven's tray.

Set It and (Almost) Forget It: You'll dial in the temperature and time. This is usually around 130°C (265°F) for two to three minutes, but always check your powder's instructions. The digital controls on most ovens make this a breeze.

Watch the Magic: Through the little window, you can see the powder melt and turn shiny. That's how you know it's working.

Cool and Store: Once the timer goes off, you pull it out, let it cool down, and it's ready to be pressed onto a shirt or stored for later.

You've got options, depending on how much you're printing:

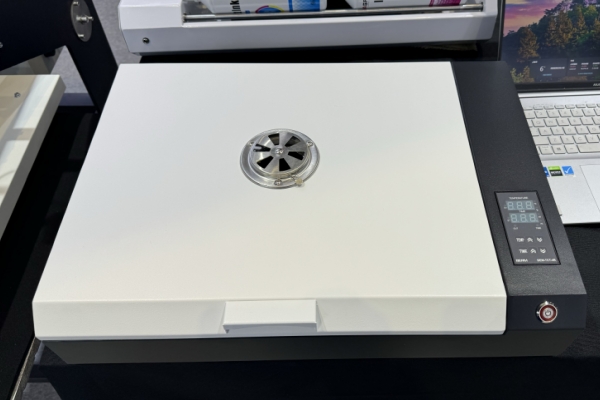

The Desktop (A3) Oven: Perfect for most small businesses and hobbyists. It fits nicely on a workbench and can handle a serious amount of prints without taking up much space.

The Larger (A2/A1) Oven: If you're running bigger sheets of film or just have a high volume of orders, you'll want the extra real estate.

The Conveyor Oven: This is the big leagues. If your shop is pumping out hundreds of prints a day, a conveyor system automates the entire curing process.

The TEXTEK DTF Oven is available in two practical sizes—a compact 30cm model and a larger 60cm version—to match your production volume without wasting space or power.

Its standout features ensure professional results:

Dual-Zone Heating: With heating elements on both the top and bottom, it cures prints evenly throughout, eliminating under-done spots.

Smart Safety Design: An anti-scalding exterior and breathable mesh ensure safe operation, while the anti-adhesion tray prevents films from sticking or tearing.

Total Control: Easily dial in the perfect cure for any powder with adjustable baking time, temperature, and a visual interface for precise settings.

Think of the DTF oven as the quality control center of your entire DTF operation. It's what ensures the time and money you’ve invested in printing actually result in a product you’re proud to sell. For vibrant, soft, and durable prints that won't peel or crack, it’s the most important partner your DTF printer will ever have.