If you want your dtf printer to work normally, you must use a consumable, which is very important to the dtf process, and you must use dtf powder to make the pattern on the PET film very good peel.There are currently two colors of dttf powder on the market, let’s take a look at these two dtf powders

What is hot melt powder?

Hot-melt powder is an indispensable material in dtf transfer printing technology. According to the composition and performance, we can divide it into PA hot-melt powder, PES hot-melt powder, EVA hot-melt powder and TPU hot-melt powder. Medium or fine white adhesive powder used to form the adhesive layer after the DTF printing process. Specially formulated thermoplastic polyurethane (TPU) hot melt adhesive powder, also known as PET film powder, rubber powder. Both white powder and black powder are available in the market.

Hot-melt powder is used in the printing of various textiles, leather, paper, wood and other materials and the preparation of various glues. The produced glue has the characteristics of water resistance, good fastness, fast drying speed, not easy to block the screen, and does not affect the color of the ink. It is a new type of environmentally friendly material.

Hot melt powder characteristics:

1. As long as the mild bonding conditions can obtain excellent washing fastness (can be washed at a temperature as high as 60 degrees) and dry cleaning fastness.

2. Soft to the touch and good resilience.

3. It has good chemical stability and can be stored at room temperature for a long time without deterioration.

4. It is a green environmental protection product that is harmless to the human body.

Uses of hot melt powder:

1. Heat transfer printing.

2. Make printing glue.

3. Screen printing.

4. Bronzing and flocking printing.

5. Make hot melt glue.

Hot-melt powder is used in the printing of various textiles, leather, paper, wood and other materials and the preparation of various glues. The produced glue has the characteristics of water resistance, good fastness, fast drying speed, not easy to block the screen, and does not affect the color of the ink. It is a new type of environmentally friendly material.

Hot melt powder characteristics:

1. As long as the mild bonding conditions can obtain excellent washing fastness (can be washed at a temperature as high as 60 degrees) and dry cleaning fastness.

2. Soft to the touch and good resilience.

3. It has good chemical stability and can be stored at room temperature for a long time without deterioration.

4. It is a green environmental protection product that is harmless to the human body.

Uses of hot melt powder:

1. Heat transfer printing.

2. Make printing glue.

3. Screen printing.

4. Bronzing and flocking printing.

5. Make hot melt glue.

It can be used in personalized T-shirts, team uniforms, work clothes, advertising shirts, jerseys, bags and other fields. The transferred image has color retention and resistance to multiple washings.

What is black powder?

Made from 100% high purity polyurethane, dtf black powder provides high performance melt adhesion for direct to textile transfer printing. The prints are not easy to peel off and can be printed on a variety of garments, making complete print transfers easy.

Benefits of using black powder:

1. It is extremely waterproof and can be washed and dry-cleaned. Thanks to its excellent flexibility, even if the T-shirt is pulled or twisted, the printed graphics are less likely to crack and deform.

2. DTF black powder is suitable for almost all DTF and DTG inkjet printers and any PET film size. This DTF black powder has excellent adhesion and durability.

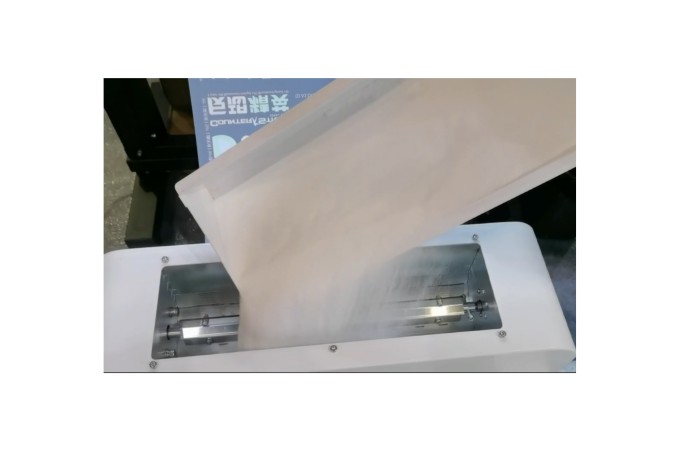

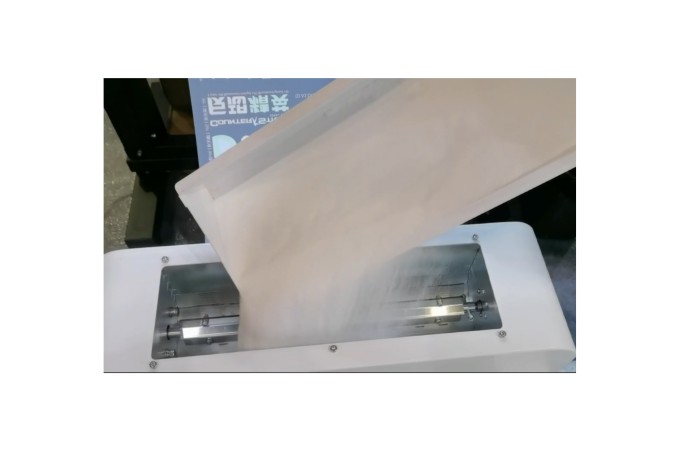

3. DTF black powder 80-200um, used with automatic powder shaking machine, will not clog, and can be applied by hand. Use hot peel PET film and cold peel PET film for high throughput. Due to the very small size of the powder, it produces fine, clear and vivid textile prints.

4. It can be printed on jeans, cotton, polyester, nylon, leather, EVA, blended and many other materials; in all shades including light and dark colors. Design on hoodies, canvas, tote bags, t-shirts, pillowcases, hats, flags, mouse pads, phone cases and more.

What is white powder?

DTF white powder is made of 100% high purity polyurethane and can be transferred directly to textiles to provide high performance melt adhesion. The prints are not easy to peel off and can be printed on a variety of garments, making complete print transfers easy.

It can be used in personalized T-shirts, team uniforms, work clothes, advertising shirts, jerseys, bags and other fields. The transferred image has color retention and resistance to multiple washings.

What is black powder?

Made from 100% high purity polyurethane, dtf black powder provides high performance melt adhesion for direct to textile transfer printing. The prints are not easy to peel off and can be printed on a variety of garments, making complete print transfers easy.

Benefits of using black powder:

1. It is extremely waterproof and can be washed and dry-cleaned. Thanks to its excellent flexibility, even if the T-shirt is pulled or twisted, the printed graphics are less likely to crack and deform.

2. DTF black powder is suitable for almost all DTF and DTG inkjet printers and any PET film size. This DTF black powder has excellent adhesion and durability.

3. DTF black powder 80-200um, used with automatic powder shaking machine, will not clog, and can be applied by hand. Use hot peel PET film and cold peel PET film for high throughput. Due to the very small size of the powder, it produces fine, clear and vivid textile prints.

4. It can be printed on jeans, cotton, polyester, nylon, leather, EVA, blended and many other materials; in all shades including light and dark colors. Design on hoodies, canvas, tote bags, t-shirts, pillowcases, hats, flags, mouse pads, phone cases and more.

What is white powder?

DTF white powder is made of 100% high purity polyurethane and can be transferred directly to textiles to provide high performance melt adhesion. The prints are not easy to peel off and can be printed on a variety of garments, making complete print transfers easy.

Benefits of using white powder:

1. It is extremely waterproof and can be washed and dry-cleaned. Thanks to its excellent flexibility, even if the T-shirt is pulled or twisted, the printed graphics are less likely to crack and deform.

2. DTF white powder is suitable for almost all DTF and DTG inkjet printers and any PET film size. This DTF white powder has excellent adhesion and durability.

3. DTF white powder 80-200um, used with automatic powder shaking machine, will not clog, and can also be applied by hand. Use hot peel PET film and cold peel PET film for high throughput. Due to the very small size of the powder, it produces fine, clear and vivid textile prints.

4. It can be printed on jeans, cotton, polyester, nylon, leather, EVA, blended and many other materials; in all shades including light and dark colors. Design on hoodies, canvas, tote bags, t-shirts, pillowcases, hats, flags, mouse pads, phone cases and more.

5. The cost is relatively low.

6. The overall picture and color of the finished product will be better.

Benefits of using white powder:

1. It is extremely waterproof and can be washed and dry-cleaned. Thanks to its excellent flexibility, even if the T-shirt is pulled or twisted, the printed graphics are less likely to crack and deform.

2. DTF white powder is suitable for almost all DTF and DTG inkjet printers and any PET film size. This DTF white powder has excellent adhesion and durability.

3. DTF white powder 80-200um, used with automatic powder shaking machine, will not clog, and can also be applied by hand. Use hot peel PET film and cold peel PET film for high throughput. Due to the very small size of the powder, it produces fine, clear and vivid textile prints.

4. It can be printed on jeans, cotton, polyester, nylon, leather, EVA, blended and many other materials; in all shades including light and dark colors. Design on hoodies, canvas, tote bags, t-shirts, pillowcases, hats, flags, mouse pads, phone cases and more.

5. The cost is relatively low.

6. The overall picture and color of the finished product will be better.

.jpg) The difference between white powder and black powder:

White powder is suitable for clothes of any fabric color, but generally, white or light-colored clothes are used.

Black powder is mainly composed of TPU rubber powder and activated carbon. It is more suitable for black or dark clothes. Commonly used are polyester, bags and other fabrics.

Unlike the DTG technique, DTF does not require preprocessing. The most important factor is DTF powder. DTF powder is specially designed for use in DTF printing process. Powder comes in 1kg/pack. Our DTF powder dries slowly and is easy to tear off cold. This will help you get a great transfer.

The feel of the garment will depend on the type of powder you use and the thickness of the ink layer. Our soft and resilient DTF powder has a better feel than traditional vinyl or other types of heat transfer materials. It is elastic and soft to the touch.

To put it simply, the effect of black powder covering the background color is better, it is easier to cover some bright colors, and the covering effect of white powder is relatively poor, but most colors are suitable for white powder.

Both white and black powders have different thicknesses:

Fine powder

Fine powder is defined as 0~70 micron particle size (such as flour)

Features: It is suitable for powder coating of small letters. It feels good, but its fastness is poor. When the air humidity is high, it is easy to stick powder to the blank space of the printing film.

Medium powder

Medium powder refers to the particle size of 70~170 microns (such as salt)

TEXTEK DTF printers all use medium and fine powders of 80~160 microns.

Features: The granular shape is obvious, but currently 85% of customers use medium powder, because compared with fine powder, this powder is easy to shake and clean. In addition, it feels better than coarse powder.

Coarse powder

Coarse powder refers to a particle size of 120-240 microns (like sugar)

Features: large gaps, clean powder shaking, good three-dimensional effect (coarse powder is recommended when it is humid in summer, or coarse powder can be used when customers require a three-dimensional effect).

The difference between white powder and black powder:

White powder is suitable for clothes of any fabric color, but generally, white or light-colored clothes are used.

Black powder is mainly composed of TPU rubber powder and activated carbon. It is more suitable for black or dark clothes. Commonly used are polyester, bags and other fabrics.

Unlike the DTG technique, DTF does not require preprocessing. The most important factor is DTF powder. DTF powder is specially designed for use in DTF printing process. Powder comes in 1kg/pack. Our DTF powder dries slowly and is easy to tear off cold. This will help you get a great transfer.

The feel of the garment will depend on the type of powder you use and the thickness of the ink layer. Our soft and resilient DTF powder has a better feel than traditional vinyl or other types of heat transfer materials. It is elastic and soft to the touch.

To put it simply, the effect of black powder covering the background color is better, it is easier to cover some bright colors, and the covering effect of white powder is relatively poor, but most colors are suitable for white powder.

Both white and black powders have different thicknesses:

Fine powder

Fine powder is defined as 0~70 micron particle size (such as flour)

Features: It is suitable for powder coating of small letters. It feels good, but its fastness is poor. When the air humidity is high, it is easy to stick powder to the blank space of the printing film.

Medium powder

Medium powder refers to the particle size of 70~170 microns (such as salt)

TEXTEK DTF printers all use medium and fine powders of 80~160 microns.

Features: The granular shape is obvious, but currently 85% of customers use medium powder, because compared with fine powder, this powder is easy to shake and clean. In addition, it feels better than coarse powder.

Coarse powder

Coarse powder refers to a particle size of 120-240 microns (like sugar)

Features: large gaps, clean powder shaking, good three-dimensional effect (coarse powder is recommended when it is humid in summer, or coarse powder can be used when customers require a three-dimensional effect).

TEXTEK's business covers many countries around the world, including emerging markets and mature markets. We have a complete sales system and are committed to using our professional knowledge and first-class service to help customers improve their digital printing business.

.jpg)

.jpg)

.jpg)