18

Aug

The demand for high-quality, durable, and vibrant custom textiles is higher than ever. From the bold graphics on a streetwear hoodie to the intricate patterns on athletic wear, consumers and brands are no longer satisfied with simple, easily faded prints. They demand photographic quality, exceptional durability, and the freedom to create on any fabric.

Enter a game-changing technology: Hybrid UV Printing on PU Film.

This isn't just another printing method; it's a significant leap forward, combining the best of digital precision with unparalleled resilience. But what exactly is it, and why should designers, manufacturers, and brands be paying attention?

At its core, this technology is a form of Direct-to-Film (DTF) printing, but supercharged with the power of UV-LED curing. Here's how it works:

Print: A specialized hybrid UV printer, like our hybrid UV Printer 3040 model, prints a mirror image of the design directly onto a clear Polyurethane (PU) film. The UV inks are cured instantly by LED lights as they are printed, resulting in sharp dots, vibrant colors, and no bleeding.

Laminate: A hot-melt adhesive powder is applied to the wet ink layer and then melted using a heat press or curing oven. This creates a strong, flexible adhesive layer on top of the design.

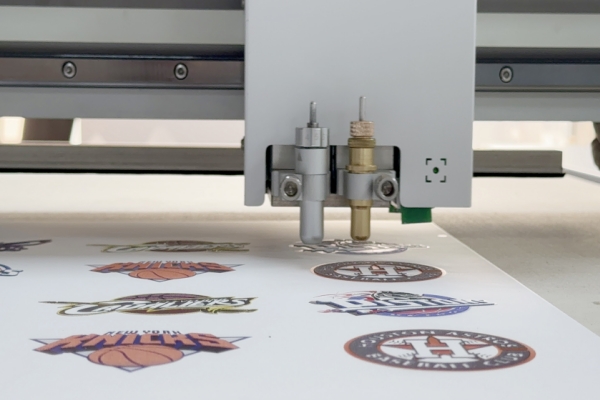

Cut: The design can then be precisely contour-cut using a DTF film cutter, ready for application.

Transfer: The final film is placed on the fabric and heat-pressed. The adhesive melts again, permanently bonding the entire design to the material. The PU film is then peeled away, leaving only the stunning, flexible print behind.

.jpg)

This innovative process solves many of the pain points associated with traditional printing methods like screen printing or direct-to-garment (DTG).

Unmatched Durability: This is the headline feature. Prints created through this method are incredibly tough. They excel in wash fastness tests, repeatedly passing rigorous soap and water wash cycles without cracking, peeling, or fading. This makes them ideal for sportswear, workwear, and everyday apparel that must withstand frequent laundering.

Vibrant Color & Detail on Any Fabric: Unlike DTG, which can struggle on dark or synthetic fabrics, this method lays down a white base layer (if needed) and vibrant colors on top of the film, which are then transferred. This means brilliant, opaque results on 100% cotton, polyester, blends, nylon, and even leather—all with the same high quality.

A Soft Hand Feel: Despite its durability, the finished print has a remarkably soft and flexible texture. It moves with the fabric, avoiding the stiff, plasticky feel of some older transfer methods, which enhances comfort for the wearer.

Efficiency and Versatility: The process is relatively quick and doesn't require the extensive setup or multiple screens of traditional printing. It's perfect for both small-batch, customized orders and larger production runs.

This technology opens up a world of possibilities for numerous industries:

Apparel Brands: Create limited-edition runs, complex designs, and incredibly durable branded merchandise.

Promotional Product Companies: Print on bags, hats, and other textile-based items with confidence in their longevity.

Sportswear Manufacturers: Meet the high-performance demands of athletic apparel that must endure sweat and constant washing.

Interior Designers: Apply custom, wash-resistant designs to upholstery, curtains, and home textiles.

Small Business Owners & Creators: Offer a superior product to clients without the high overhead of traditional screen printing.

The hybrid UV printing process on PU film is more than just a new tool; it's a paradigm shift. It bridges the gap between digital design freedom and industrial-grade durability. For anyone creating on fabric, understanding and adopting this technology is not just an option—it's an investment in delivering the quality and resilience the modern market demands.

The future of textile design isn't just about what's on the fabric, but how it's put there.