Why buy a DTF printer? Here are seven reasons why choosing a dtf printer is an excellent choice for your printing business.

Direct film printing involves printing the design onto a special film, applying and melting a powder adhesive to the printed film, and then pressing the design onto the garment or merchandise. You will need transfer film and hot melt powder, as well as software to create your prints - no other special equipment required!

1. Applicable to a wide range of materials

While direct-to-garment printing works best on 100% cotton, DTF works on many different garment materials: cotton, nylon, treated leather, polyester, 50/50 blends, and light and dark fabrics. Transfers can even be applied to different types of surfaces like luggage, shoes, and even glass, wood, and metal! You can expand your inventory by applying your designs to various items via DTF.

2. No preprocessing required

If you already own a DTG printer, you're probably very familiar with the pre-processing process (not to mention drying time). The heat applied to DTF transfers bonds the print directly to the material, meaning no pre-treatment is required!

3. A small amount of white ink

DTF requires less white ink – around 40% white, compared to 200% white for DTG printing. White ink tends to be the most expensive because it is used in greater quantities, so reducing the amount of white ink used when printing can save considerable money.

4. More durable than DTG printing

There's no denying that DTG prints have a soft, almost tactile feel because the ink is applied directly to the garment. While DTF prints don't have the soft feel that DTG has, the transfer is more durable. Direct film transfers are washable and flexible, meaning they won't crack or peel, making them ideal for items that get heavy use.

5. Easy to apply

Printing on film transfers means you can place your designs on hard-to-reach or inconvenient surfaces. If the area can be heated, you can apply a DTF design to it! Because the design adheres with just heat, you can even sell printed transfers directly to your customers and allow them to lighten the design to any surface or item of their choice, with no need for special equipment!

6. Faster production process

Since you can eliminate garment pre-processing and drying steps, you can significantly reduce production time. This is good news for one-off or small-volume orders that have traditionally been unprofitable.

7. Help your inventory become more diverse

While it may not be feasible to print a large number of your most popular designs onto every garment size or color, with DTF printing you can print popular designs ahead of time and store them using very little space. Then you'll have your best-selling product ready to apply to any garment as needed!

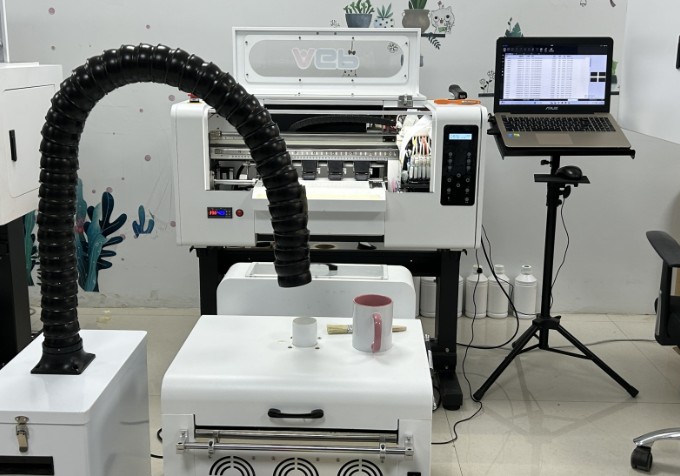

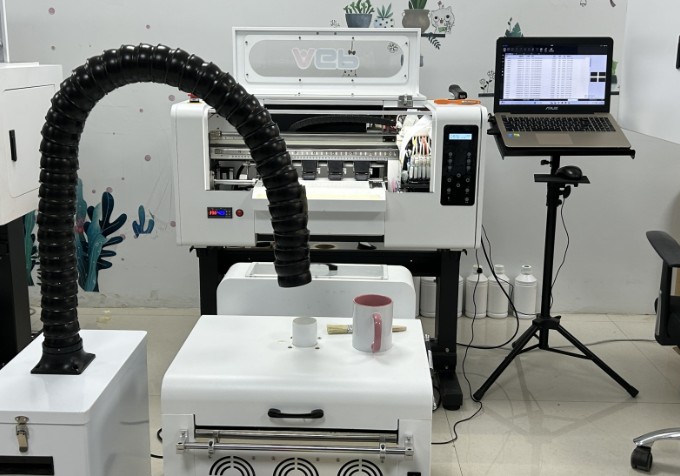

Printing environment required for DTF

For DTF printers, the first thing we need to discuss is your space setup.

The main factors that have a huge impact on DTF print quality are the environment and climate of the room where the printer and curing unit are located.

We’re talking both temperature and humidity. Without the right controlled environment, you’re going to run into print quality issues like banding in your prints. Banding looks like an old inkjet printer you used to have at home when it was running out of ink. You get a whole bunch of lines in your art and it just doesn’t look professional.

When this starts to happen, it's most likely due to ink drying and the device's actual printhead becoming clogged, which will result in time spent troubleshooting and cleaning, and possibly even replacement parts.

It's no fun when you're just trying to print t-shirts.

Not only do you need a climate-controlled space, but you also need to install a proper ventilation system. Using these printers can create health hazards in your workspace.

Curing adhesive can produce harmful chemicals, so for larger stores with proper ventilation systems, this may not be a big issue if you already have one installed.

But for a small home business or T-shirt brand, say, run out of a garage, this can result in expensive and noisy ventilation systems to minimize the hazard, not to mention exposing others to the stuff.

Even small benchtop equipment may require proper ventilation or personal protective equipment for your health and safety. This is always something to keep in mind.

Consumables

Consumables

To print on DTF transfer paper, you need to purchase hot melt powder, ink, and film.

These are not all the same, so you will need to do your research to find out which product is best for you and gives you the quality you want to provide your customers.

Depending on the material, it will also change your transfer application capabilities - there's hot peel DTF, there's cold peel.

These will affect what you can apply a DTF transfer to. Without lower temperature applications, you may find that while it can print on polyester and cotton and everything in between, you may be limited to cotton garments to avoid scorching the material.

In addition to finding the raw materials that work best for you, be aware that you may be plagued by inconsistencies in the raw materials you purchase. There are bad batches of hot melt powders, films and even inks. This can lead to expensive waste, not only in terms of time, but also money if you can't return the product.

Maintenance of dtf printer

DTF printers require routine maintenance to work better. The following are the daily maintenance procedures for DTF printers.

1. Before turning on the DTF printer, check whether there are objects stacked above and around the printer to ensure that the area around the machine is clean.

2. Before printing, check whether both sides of the printer are parallel, otherwise the printed pattern will be uneven.

3. It is recommended to clean the print head before printing every day or once every 2-3 days.

4. Check the remaining amount of ink every day and add it promptly after use to avoid air being sucked into the ink tube.

5. Reset the print head after printing, because there is a sealed protective cover inside the printhead. Initial position, not easy to block, ensuring the service life of the printhead and machine.

6. Only turn off the power and network cable after the printer is completely shut down, otherwise the printing port and computer mainboard will be seriously damaged.

TEXTEK DTF printers (direct to film printers) work on all fabrics and are perfect for custom garment printing. You can expand your inventory by applying your designs to various items via DTF. With the advancement of DTF technology, it is undeniable that DTF is taking the printing industry by storm. It is quickly becoming one of the most popular technologies for textile printing compared to traditional printing methods.

TEXTEK's business covers many countries around the world, including emerging markets and mature markets. We have a complete sales system and are committed to using our professional knowledge and first-class service to help customers improve their digital printing business.

.jpg)

.jpg)