Custom printing is simple, beautiful, and has less expenses as compared to other techniques of printing. It has been on the rise of printing clothes and other fabrics as it erases conventional techniques of printing. Considering the present days' development and progress in 3D printing technologies, it is imperative to compare DTF with other types of printing methods, such as screen printing and direct-to-garment (DTG) printing.

Equipment Required for DTF Printing

If you aspire to venture into DTF printing, here are some equipment you must consider knowing and requiring. Some of the gadgets and consumables you will need for the DTF printing process include the following:

1. DTF Printer: A good printer should use high-quality DTF inks. You will need a good DTF printer with high-quality DTF inks. Good DTF printers help you print fine details of the design and make the colors vivid.

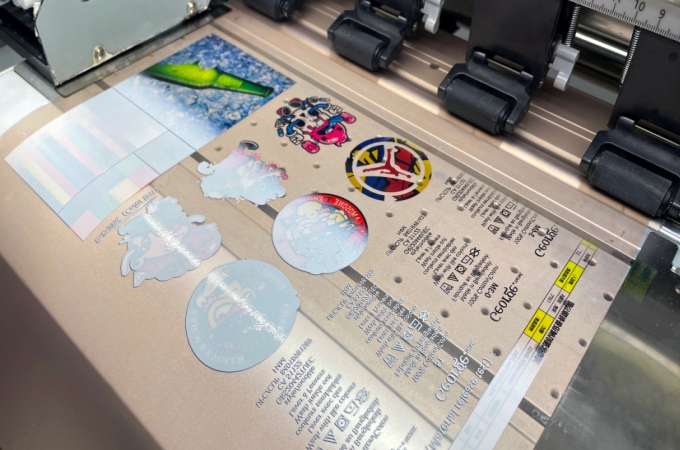

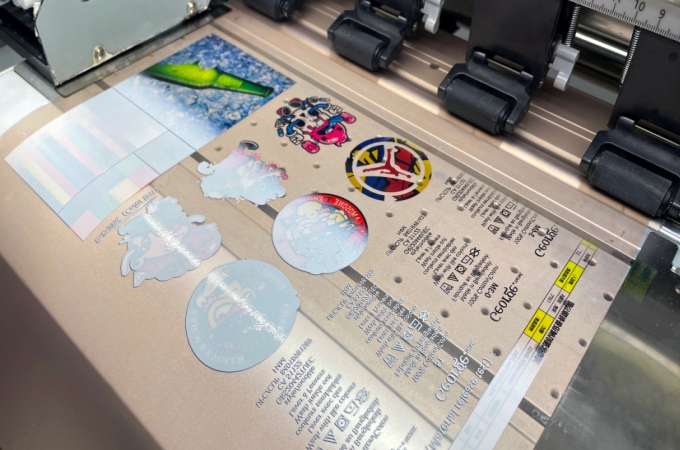

2. Transfer Film: This is a kind of DTF PET film on which your designs are printed before being transferred to the fabric surface. This film is useful in the recording of minute details as well as preserving a good quality color.

3. Hot Melt Powder: When the design has been placed on the transfer paper you have to use DTF hot melt powder. This powder aids the design to stick to the fabric adequately in the heat transfer process.

4. Heat Press Machine: The heat press machine then applies the design to the fabric being used. The heat and pressure applied in each case should be uniform to produce the best cooker results.

5. Heat Transfer Adhesives: These adhesives assist in holding the print in place on the fabric to ensure that the design does not fade away after washing.

DTF printing can produce high-quality prints with tremendous flexibility, which goes a long way in helping you scale up production and meet the ever-increasing demands of your clientele.

How does DTF Printing Work?

DTF printing is quite easy, but several things must be done carefully. Here’s a step-by-step breakdown of how it works:

1. Design Preparation: First, use the graphic design software to create your design. This step is very important to check whether the colors, shapes and other details of the design are user-friendly.

2. Printing the Design: Once you agree, it is printed on a transfer film using DTF ink or a digital printer. DTF is different from other techniques that work by printing the design directly on fabrics; instead, it uses a film to transport the design.

3. Applying Hot Melt Powder: When the design is printed, the hot melt powder is applied to the wet ink on the paper. This powder also helps to hold the print in place before the heat press process so that the print will stick to the fabric.

4. Heat Pressing: In this process, a fabric with a printed design is put onto the fabric and a heat press machine is used to transfer the design. Compared to the other powder adhesives, this type is set at higher heat to ensure that the design is permanently fixed on the fabric.

5. Peeling the Film: Once the material is through the heat press, the film is peeled off to reveal a well-set, vibrant, and long-lasting print on the material.

Pros of DTF Printing

1. Versatility Across Fabrics: Another advantage of DTF printing is that the printing process can work with various designs and on different materials such as cotton, polyester, nylon and leather. Thus, it can be used where a business needs to offer various printing services.

2. Lower Setup Costs and Shorter Turnaround Times: DTF printing is less cumbersome as compared to screen printing to the extent that there isn’t so much use of the screens for the colors printed. This makes it cheaper for smaller productions of cycles especially when designing involves complex images using many colours. Due to the relatively small amount of time required to prepare its equipment, a client can receive their peculiar pieces of production with DTF printing.

3. High-Quality Prints: DTF prints are valued because of their sharp colors and good definition of the finer details, which is perfect for detailed designs. DTF does not have the issues that screen printing does have when it comes to multicolor or gradient designs.

4. No Minimum Order: DTF does not need custom screens, and therefore, you can design one shirt or produce a small number of Shirts at a very low price because you’ll not need large amounts of capital to develop screens to ensure that the design is printed has screens made for it. This is especially beneficial for companies that deal with customized or made-to-order products.

Cons of DTF Printing

1. Slower for High-Volume Orders: DTF printing is better for small-scale orders than large-scale production, although it might not be as efficient as screen printing. However, it may still be quicker and cheaper to use screen printing for large runs of a design.

2. Specialized Consumables: DTF is a specialized technique that necessitates using consumables such as transfer films and hot melt powder, which can be pricey and, sometimes, more difficult to obtain than regular inks or screens.

3. Steep Learning Curve: One does not need a professional printer to operate the DTF printer, but some basic technology skills are important, especially in setting the temperature and pressure of the printer to suit different materials. It is not complicated, but it can take time and practice to do it correctly.

Traditional Printing Methods: An Overview

Traditional printing methods include screen printing and DTG printing.

Pros of Screen Printing

- Cost-Effective for Bulk Orders: This printing process is relatively cheaper if there is a large number of screens to be printed; therefore, it is common with firms that have a constant flow of orders. The time and cost required to produce each additional unit are relatively low once the initial setup is complete.

- Durable Prints: With screen printing, you can develop designs with a permanent feel. The ink is absorbed in the fabric so it does not fade or crack and keeps the same look after washing the cloth many times.

- Vibrant Colors on Simple Designs: Screen printing is good for creating brand logos, badges, mascots, emblems, team wear, or branded merch.

Cons of Screen Printing

- High Setup Costs for Small Orders: Screen printing is too expensive for small runs or for printing custom designs. Each color needs its own screen; hence, it takes time and costs more to produce the T-shirts.

- Limited Detail: As mentioned earlier, screen printing is not suitable for designs with gradients or very fine details. When the patterns are many and in many colors, the process can get out of hand and become very expensive.

- Environmental Impact: Screen printing uses more chemicals and ink. This printing method harms the environment if the producers do not take the right precautions.

Pros of DTG (Direct-to-Garment) Printing

- Excellent for Detailed Designs: DTG printing is most effective in complex designs, particularly those with great color density or photorealism.

- No Setup Costs: Like DTF printing, DTG does not involve setup costs. This makes it suitable for small orders and products with complex designs.

Cons of DTG Printing

- Fabric Limitations: DTG can only be printed on 100% cotton fabrics; and not on polyesters and other synthetic fabrics. This is why DTF printing has a clear upper hand as it is versatile to work on more diverse textiles.

- Durability Issues: DTG prints are bright; however, the brightness may fade with time if washed many times, and the difference is as compared to DTF or screen printing.

Conclusion

There you have it. Now, you know the strengths and limitations of each method, and you can make an informed choice that meets your production goals and helps grow your business in the competitive world of custom printing. Remember that when choosing between DTF printing and conventional printing techniques, the decision greatly depends on your specific business model, target audience, and quantity.

Drop us an email and let's make great things happen: info@textek.com

Contact us through WhatsApp and let's talk furthermore: +8619137185989

.jpg)

.jpg)