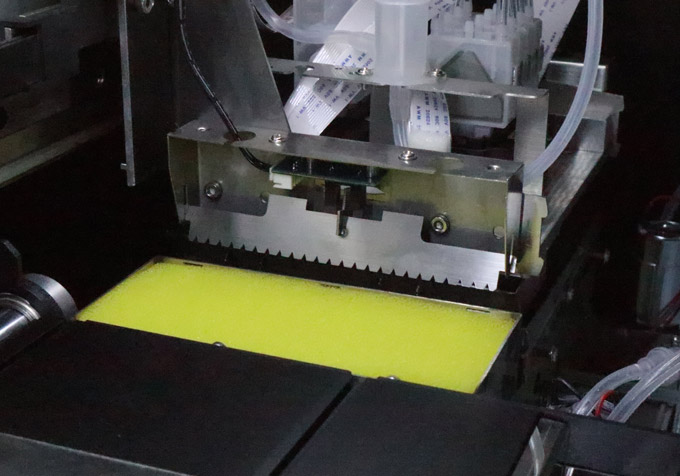

Capping station of

DTF printer is located on right side of printing machine frame. It is an indispensable part, which plays a role in protecting and maintaining print head. In order to keep nozzle moist and reduce solidification of ink to block nozzle, it is necessary to clean up waste ink in capping station in time.

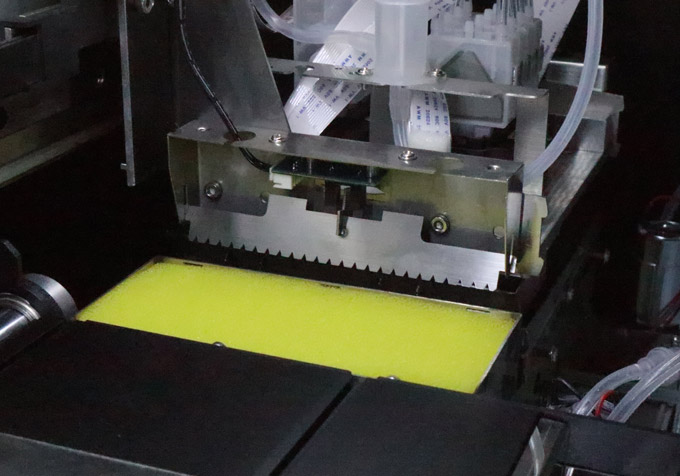

1. Wiper should be wiped clean with a cotton swab dipped in cleaning fluid every day.

2. Ink accumulation in ink accumulation guide groove of wiper blade should also be cleaned up every day.

3. Ink guide tank of capping station should also be cleaned every day.

4. Before DTF shirt printer shuts down every day, drip cleaning fluid into cap to flush waste ink tube clean to prevent waste ink tube from being blocked.

5. Scraper slide should also be cleaned up to reduce resistance of scraper back and forth movement.

6. Ink accumulation on protective plates on both sides of print head should also be cleaned up every day to prevent ink accumulation from rubbing against paper during printing.

Capping station is kept in best condition at all times to provide more comprehensive protection for DTF printer head.

Textek printing factory (

www.textek.cn) is a leading manufacturer & supplier of advanced digital textile printing machine.We supply DTF Printers, Sublimation Printers, Direct Fabric Printers, Printing Media, and other supplies.

Textek's business covers many countries around the world, including emerging markets and mature markets.We have a complete sales system and are committed to using our professional knowledge and first-class service to help customers improve their digital printing business.