18

Oct

Technological advancements in custom printing are always on the rise and this has brought about the advent of DTF printing. DTF in digital printing means Direct to Film and is a new, versatile technique, empowering for both business owners and consumers.

If you've ever wondered how the fancy prints on shirts, phone cases, and other items are made, DTF printing is one of the many techniques that make that happen. Let's take a closer look at this process and you can learn all about how it works.

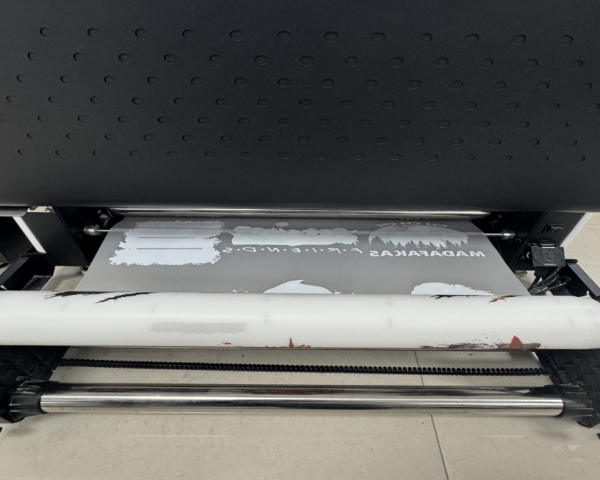

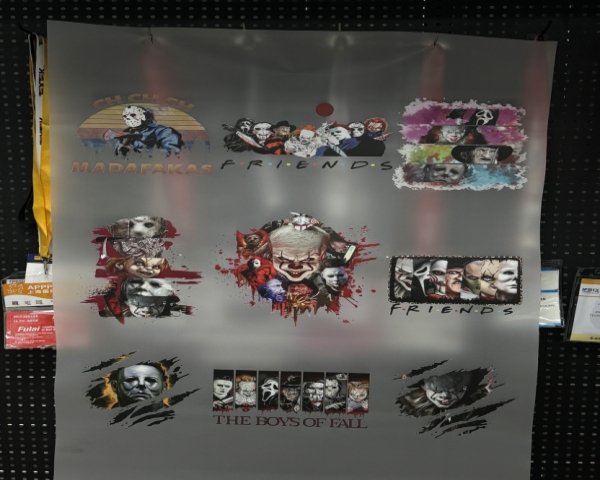

Why print directly onto your fabric when you can print high-resolution designs onto a DTF PET film and then transfer them onto any item of choice?

This is what a DTF Printer can help you achieve. Using specialized inks, your design is printed onto a PET film. By heat pressing this film onto different mediums, you get lasting designs with top-of-the-shelf quality.

In the world of custom printing, DTF is not the only option available. Let’s compare and contrast DTF with DTG (direct-to-garment) printing and see why DTF printing stays winning.

Unlike DTF where a PET film (the DTF transfer) is heat pressed onto a medium, a DTG printer takes the ink and applies it directly onto the chosen surface.

A major selling point of DTF printing is the sheer brilliance and vibrancy of prints it can achieve. Its ability to absorb inks and the drying methods used ensures its durability over a long period of time.

DTG printing is mostly great for production of smaller numbers of items. If you need to produce full-color designs at scale then a DTF Printer is what you need!

Each DTF printing process typically begins by printing digital designs onto a PET film. The printed design is then covered with adhesive powder which sticks to the ink.

Sounds interesting, right? Now let's take a step-by-step look at the DTF printing process

Now that we have laid the groundwork by explaining what direct-to-film printing is and how it works, it's time to dive into software and ink.

Having explored how a DTF Printer works and what distinguishes it from other methods of custom printing, it’s important to ask how we can put all this information to use.

Operating DTF printing begins with choosing the right software and the most important criterion to consider is the compatibility of your software of choice with your DTF Printer.

Incompatibility of software and DTF printers can disturb or completely halt your printing process resulting in discouragement and eventual loss of profits.

In addition, you should go for software options that allow easy transfer of files between devices. Also, watch out for ones with routine updates and excellent customer service.

To ensure your designs come out as envisioned, opt for software with a variety of options like color management, layering, and conversion of shapes into dots or lines (rasterization).

Again, we must start with compatibility. The inks you pick for your DTF Printer must be those specific to the type of Printer and film. Poor quality of prints and eventual damage to DTF printers are usually a result of bad ink choices.

Durability remains a major selling point of DTF printers and choice of ink plays a vital role. By ensuring you select inks with a reputation of lasting long, you'll end up with happy customers and a thriving business.

The mechanism of DTF printing uses specialised printers that are compatible with specific inks and PET film. Regular printers do not come with any of these components and so cannot print DTF.

There's no fixed price for DTF printing. The cost depends on various factors ranging from size of the design and the volume of items. However, in situations where a full-color design is needed or a smaller volume of items is to be printed, a DTF print is known to be a better cost-effective choice.

The type of surface printed on, the quality of ink used, and the care of the prints after printing are some of the factors that determine the durability of DTF prints.

With adequate after-production care, properly curated DTF prints can remain in pristine condition without fading, cracking or washing for up to 2 to 5 years.

Custom printing has not remained the same since the emergence of DTF printing. Businesses and individuals now have at their disposal the perfect technique for bringing to life all of their ideas.

Now that you understand what DTF printing is, the process and what sets it apart from other printing methods, you can now decide if it's the spark your print business has been missing out.

Drop us an email and let's make great things happen: info@textek.com

Contact us through WhatsApp and let's talk furthermore: +8619137185989