Understanding UV DTF Printing

.jpg)

.jpg)

UV DTF printing is a relatively recent advancement in the field of digital printing. It integrates UV technology with direct-to-film printing, allowing for vibrant, durable prints on a multitude of substrates. This technology has evolved to meet the growing demand for fast, efficient, and versatile printing solutions.

Key Features

The versatility of UV DTF printing is one of its standout features. It enables printing on a diverse range of materials, including plastic, glass, metal, wood, and even textiles. The process involves printing on a special UV DTF film, which can then be transferred to the desired substrate. This method is particularly advantageous for its ease of use and cost-effectiveness, as it requires minimal setup and maintenance compared to traditional printing methods.

Applications

UV DTF is ideal for customized apparel, small promotional items, and intricate designs. It is a preferred choice for businesses focused on personalized products due to its ability to produce high-quality, detailed prints with minimal color variation. Industries such as fashion, advertising, and gift manufacturing frequently utilize UV DTF for its adaptability and efficiency in producing small to medium-sized batches.

Pros and Cons

The flexibility of UV DTF printing is a significant advantage, allowing it to cater to a wide range of industries and applications. Additionally, the lower setup costs make it accessible for small businesses and startups. However, UV DTF does have its limitations. The size of prints is often restricted compared to other methods, and the durability of prints, while sufficient for many applications, may not match that of UV Flatbed prints in demanding environments.

Understanding UV Flatbed Printing

UV Flatbed printing represents a more traditional approach to UV printing, characterized by its ability to print directly onto rigid materials. This technology has undergone significant advancements, evolving from simple flatbed printers to sophisticated machines capable of handling large-scale and high-resolution projects.

Key Features

UV Flatbed printers are renowned for their ability to print on a wide array of rigid materials, including wood, metal, glass, and acrylic. The high-quality output and precise color reproduction make them suitable for applications requiring superior image quality and detail. The use of UV-curable inks ensures that prints are immediately dry and resistant to environmental factors, enhancing their durability and longevity.

Applications

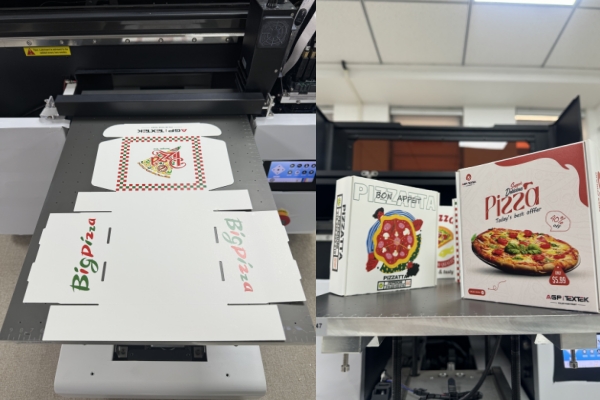

UV Flatbed printing is perfect for signage, packaging, and large-scale projects. It is extensively used in industries that require robust and visually striking graphics, such as retail, exhibition, and architectural design. The ability to print large images directly onto a substrate without the need for intermediate processes makes UV Flatbed an efficient choice for high-volume production.

Pros and Cons

The high-quality and durable prints produced by UV Flatbed printers are unmatched, making them ideal for projects that demand longevity and detail. However, these benefits come at a cost. The initial investment for UV Flatbed printers is typically higher, and the machines require more maintenance. Additionally, their energy consumption is greater, which can lead to higher operational costs over time.

Comparing UV DTF and UV Flatbed Printing

The Technical Divide – Direct vs. Transfer

While both technologies rely on UV-curable inks and UV light for instant curing, their core workflows differ fundamentally, resulting in distinct application capabilities.

1. UV Flatbed Printing: The Industrial Standard

UV Flatbed Printing represents the traditional, direct approach. The process involves placing a rigid material, known as the substrate, directly onto a flat printing bed. The print heads then jet the ink onto the surface, which is immediately cured by powerful UV lamps.

This direct printing method creates an extremely strong, permanent bond between the ink and the material. It is the preferred choice for applications requiring superior image quality, precise color reproduction, and unmatched durability. Flatbed printers are renowned for handling a wide array of rigid substrates such as wood, metal, glass, and acrylic, making them ideal for large-scale, high-resolution projects.

2. UV DTF Printing: The Flexible Solution

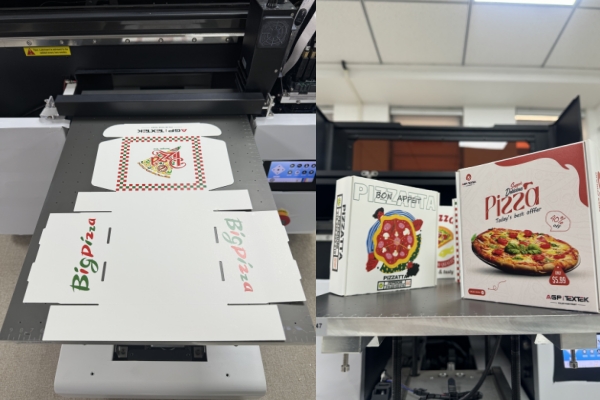

UV DTF Printing is a newer, two-step transfer printing method. Instead of printing directly onto the final product, the UV ink is first printed onto a specialized A-film (PET release film). This printed film is then laminated with a B-film (positioning film). The resulting decal is peeled from the A-film and manually transferred onto the final product.

This innovative process is the key to UV DTF's versatility. It allows the final design to be applied to virtually any shape, including curved, irregular, or cylindrical surfaces like water bottles, mugs, and helmets, which are impossible to print directly on a flatbed machine. This flexibility makes UV DTF a powerful tool for custom promotional items and personalized merchandise.

Performance Comparison – Quality, Durability, and Speed

When evaluating these technologies, businesses must weigh the trade-offs in print quality, longevity, and production speed.

Print Quality and Durability

UV Flatbed printers generally produce superior results for high-resolution images and graphics, offering a level of detail and color precision that is hard to match. Crucially, the durability of a flatbed print is often unmatched, as the ink is fully integrated and resistant to environmental factors, making it perfect for outdoor signage and high-wear industrial applications.

UV DTF offers impressive print quality suitable for most applications, especially where flexibility is prioritized. The final transferred decal often has a unique, glossy, and slightly raised tactile finish. However, as the design is essentially an adhesive film, its durability, while sufficient for many uses, may not match the extreme longevity of a direct flatbed print in demanding environments.

Production Speed and Workflow

In terms of raw printing speed, both technologies can be fast. However, overall production efficiency differs significantly:

•UV Flatbed: Excels in high-volume, automated runs of flat items. Once the substrate is loaded, the printing process is one-step and rapid, leading to a high throughput for standardized orders.

•UV DTF: Stands out due to its quick setup and the ability to print transfers in advance. While the printing itself is fast, the overall cycle time is limited by the manual transfer process, making it ideal for rapid production cycles of small to medium-sized batches.

Cost Analysis and Business Suitability

The financial model for each technology caters to different business scales and budgets.

|

Factor

|

UV Flatbed Printing

|

UV DTF Printing

|

|

Initial Investment

|

High (Sophisticated, industrial-grade machinery)

|

Low to Moderate (Accessible for small businesses/startups)

|

|

Consumable Costs

|

Lower (Primarily ink and cleaning fluid)

|

Higher (Requires specialized A-film, B-film, and adhesive)

|

|

Operational Costs

|

Higher energy consumption (though LED technology is improving) and maintenance

|

Lower maintenance, but labor-intensive transfer process

|

|

Best For

|

Signage, architectural design, large-format graphics, industrial components

|

Customized apparel, small promotional items, curved drinkware, intricate designs

|

The UV Flatbed Printer requires a significant initial investment, often placing it out of reach for startups. However, for businesses focused on large-scale projects and high-volume production, the lower consumable cost and high automation lead to a lower cost per unit over time.

The UV DTF Printer offers a much lower barrier to entry, making it an economical choice for small businesses and those specializing in personalized products. While the consumable costs (films and adhesives) are higher, the lower initial investment and the ability to quickly produce high-margin custom items provide a compelling return on investment for flexible, short-run work.

Conclusion: Making Your Strategic Choice

The decision between UV DTF and UV Flatbed Printing should be a strategic one, guided by your core product offering and target market.

If your business is built on industrial durability, large-format signage, and high-volume, standardized production of flat, rigid items, the UV Flatbed Printer is the essential, high-performance tool for your operation.

If your focus is on personalized merchandise, custom branding on curved or irregular objects, and you require a cost-effective, flexible solution with a quick turnaround for small to medium batches, the UV DTF Printer is an innovative technology that unlocks new revenue streams in the customization market.

By carefully assessing your budget, production volume, and the shape of the products you intend to print, you can select the UV printer technology that will best position your business for future growth and success.

.jpg)

.jpg)