07

Jan

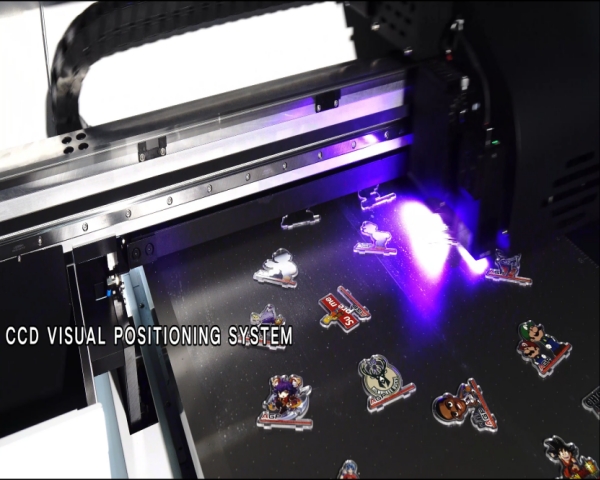

UV printing has completely changed how we print on different materials due to its accuracy, efficiency, and flexibility. Amongst other modern developments in this sector, there is the highly important and highly renowned CCD Visual Positioning System.

CCD offers perfect alignment when printing and that is why it is advisable to always use it when working with sensitive projects. We will discuss what a CCD Visual Positioning System is, how it operates, and why it is so crucial in UV printing.

A CCD Visual Positioning System uses advanced imaging technology to identify and adjust the position of materials on a UV printer’s bed. It contains a high-resolution camera paired with software to align the designs correctly.

The components of a CCD Visual Positioning System are:

The CCD Visual Positioning System follows the following process to deliver perfect results:

CCD camera is used in the printers to scan the surface of the material placed on the printer bed. This scan determines the position of the substrate, its shape, and the existing markers or prints.

The image processing unit includes the scanned data with the design to be printed. It detects any offset that may exist between the actual position of the substrate and the layout design on the substrate.

The system provides data to the printer’s control unit to maintain precise alignment with the substrate.

After the alignment is confirmed, the printer actualizes the design and is keen throughout the process to ensure that the alignment is correct.

The CCD system enables the design to be printed with the right orientation on the substrate without the design having to be shifted manually to the correct position. This feature is particularly useful when it comes to pre-printed products.

When the alignment process is automated, it cannot be spoiled by the hand of a designer, and that is always a good thing. CCD is time-saving and precise, and this, in turn, makes it efficient in its work.

Whether it is a flat surface, a cylindrical, or some irregular form, the CCD Visual Positioning System is capable of detecting all of them.

Misalignment during printing means waste. With perfect alignment, the CCD system plays its part in saving the planet.

A CCD system is beneficial for high-volume printing companies because it gives the company consistency in all its prints.

The CCD Visual Positioning System is used in several applications, the most common are mentioned below:

When applying designs onto items that are printed such as labels, business cards, or any packaging material, the CCD system ensures the correct positioning of the new design such that it does not overlap or is misplaced on the existing printed images.

The application of CCD positioning provides a much easier and more accurate way of printing on irregular shapes and textured objects such as bottles, curved glass, or wood.

Small or complex areas like custom mugs, phone cases, or promotional products are usually too small for traditional printing. The CCD system ensures precision in the alignment of these designs.

In projects where precision is important, the CCD system saves the day, especially in applications such as printing on circuit boards or tiny parts.

CCD-equipped UV printers can print on pre-sewn items and can easily print in line with seams or patterns.

Higher-resolution cameras will capture more detail so the system will be able to detect tiny misalignments.

Look for software with easy controls and lots of features as software is the backbone of any system as it can make or break the operation.

Ensure the printer you choose is compatible with the materials you intend to use.

High speed is desirable but precision should not be compromised. Test the printer’s precision at different production speeds.

Choose a printer with easily replaceable and long-lasting components. Check the manufacturer’s guidelines for maintenance instructions and choose one that requires low maintenance.

Traditional UV printers can make great prints but those with CCD Visual Positioning Systems have several advantages over the former:

Real-Time Adjustments:

Traditional printers use static setups, and CCD systems adjust on the fly during printing.

Higher Customization:

For personalized or pre-printed substrates CCD printers are unbeatable.

Faster Setup:

Automatic alignment is much faster than the manual adjustments commonly performed on traditional printers.

The CCD Visual Positioning System is a revolution in UV printing due to its accuracy, versatility, and efficiency. It automates alignment and allows real-time adjustments, eliminating complex print jobs' challenges. Whether you’re in personalized products, high-precision electronics, or creative design, a UV printer with a CCD system is an investment that will take your output and productivity to the next level.

As the industry moves forward, CCD visual positioning will be the norm, so get ahead of the game and deliver the perfect print every time.