UV DTF printing technology uses ultraviolet light to quickly cure (or dry) the ink on the printed substrate. This reduces production time compared to other digital printing technologies such as latex or solvent inkjet printing. It also produces sharp images with vibrant colors that won't scratch, fade and crack over time. It is also an environmentally friendly procedure that does not use any harmful chemicals.

What is uv dtf?

UV dtf, it is to print glue, isolation, pattern, hot stamping, and varnish layer by layer on special PP release paper to form patterns, trademarks, etc., and then cover the transfer film, and then use the transfer film to transfer the pattern. A decoration process on the surface of objects, it is named UV DTF because of its three-dimensional and crystal-like appearance.

Features of UV DTF process

1. UV DTF is one-stick, one-tear and ready-to-use, convenient and fast, which perfectly solves the vacancy of printing irregular shapes, and breaks through the limitation that patterns can only be printed on flat panels.

2. UV DTF has very obvious advantages over ordinary labeling, with bright patterns, rich colors, strong three-dimensional effect, high gloss, easy to carry and separate when transferring, leaving no residual glue.

3. Saves labor. Compared with silk screen printing and transfer printing, if UV printing is used, one person can complete the printing, which reduces labor costs for enterprises.

4. Pollution is reduced. Compared with weak solvents and the unpleasant and pungent smell of silk screen printing. UV ink greatly reduces pollution.

Application of UV DTF

Application of UV DTF

1. UV DTF can generally be attached to hard and smooth surface materials: such as packaging boxes, tea cans, paper cups, notebooks, tin cans and aluminum boxes, plastics, stainless steel, ceramics, etc.

2. It is not recommended to stick on soft materials, such as cloth, leather, silica gel, tempered glass, glazed ceramics or the surface of rough frosted products, etc. Although it can be pasted, the firmness and durability will be greatly reduced decline.

UV DTF is a cutting-edge solution in the intersection of UV printing technology and DTF printing technology. Instead of using UV ink (and varnish) to print onto the UV DTF surface directly onto the substrate, you can then transfer the UV print to the substrate in a two-step process. Instead of using a UV printer to print directly to hard objects (which can be limited in production due to the fact that you can only print 1 object at a time, or only on irregularly shaped materials), you can print illustrations with your UV printer to a UV DTF sheet , one image at a time, or multiple images at a time, basically creating a UV printed sticker. Then simply peel and transfer your UV "sticker" to your hard object. Ideal for irregular, curved materials and very tall or oversized materials that might otherwise not be directly printable).

There are many types of UV DTF films on the market. TEXTEK will list them one by one for everyone.

1. Ordinary UV DTF film

Printable Film (Film A)

Material: There are paper base and transparent base materials to choose from. The surface of the printed base film is coated with glue and covered with a protective layer.

Specifications: There are sheet specifications and roll specifications to choose from.

Positioning film (Film B)

Material: release film

Ordinary UV DTF film also has soft film and hard film to choose from. Hard film is more suitable for hard surface materials such as glass, metal, wood and so on. Soft film is more suitable for some materials with soft surface, such as plastic bags, plastic bags, PVC and so on.

TEXTEK has tested all these types with stable results, please feel free to send us an inquiry.

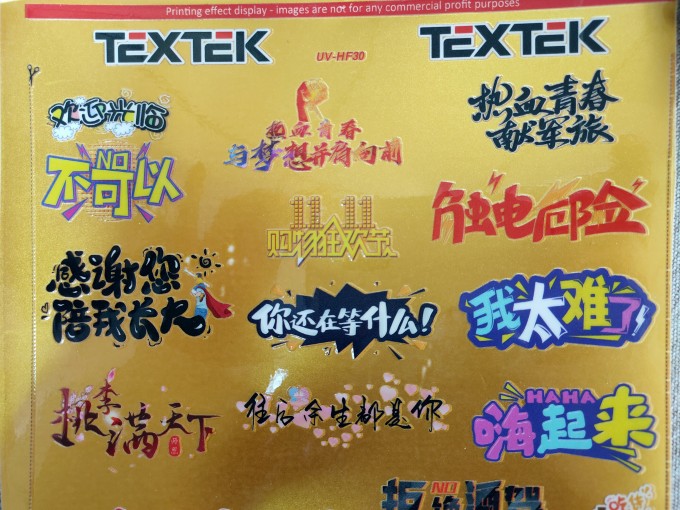

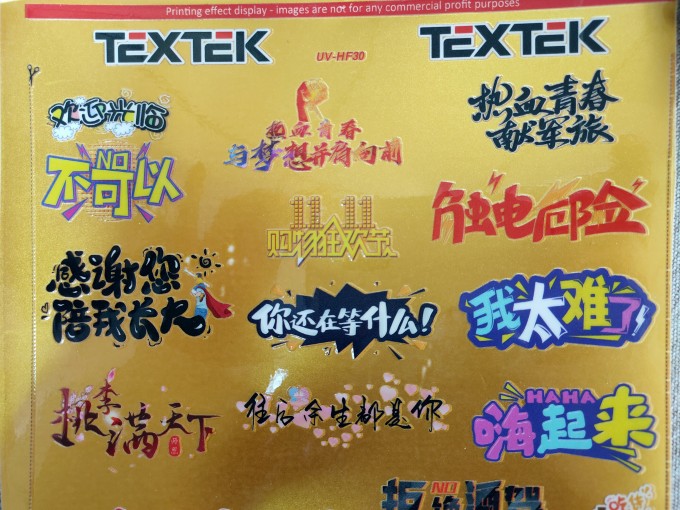

2. Glitter UV DTF film

TEXTEK also makes some special solutions for UV DTF printing film. So now, we have glitter effect on UV DTF products, which is an innovation.

Different from the common UV printing A Film on the market, this new glitter UV DTF Film can create a magical color effect and make you feel fresh.

Printable Film (Film A)

Material: It will have glitter material. The surface of the printed base film is coated with glue and covered with a protective layer.

Specifications: There are sheet specifications and roll specifications to choose from.

Positioning film (Film B)

Material: release film

3. Gold/Silver film

Different from the common UV printing A Film on the market, this new Golden UV Film can create the same bronzing effect.

Printable Film (Film A) Material: It will have gold/silver based material. The surface of the printed base film is coated with glue and covered with a protective layer.

Specifications: There are sheet specifications and roll specifications to choose from.

Positioning film (Film B)

Material: release film

The above are the types of UV DTF films organized by TEXTEK for you. There are various options for you to choose from. Welcome to consult at any time!

TEXTEK's business covers many countries around the world, including emerging markets and mature markets. We have a complete sales system and are committed to using our professional knowledge and first-class service to help customers improve their digital printing business.

.jpg)

.jpg)